INTRODUCTION 1

1-4

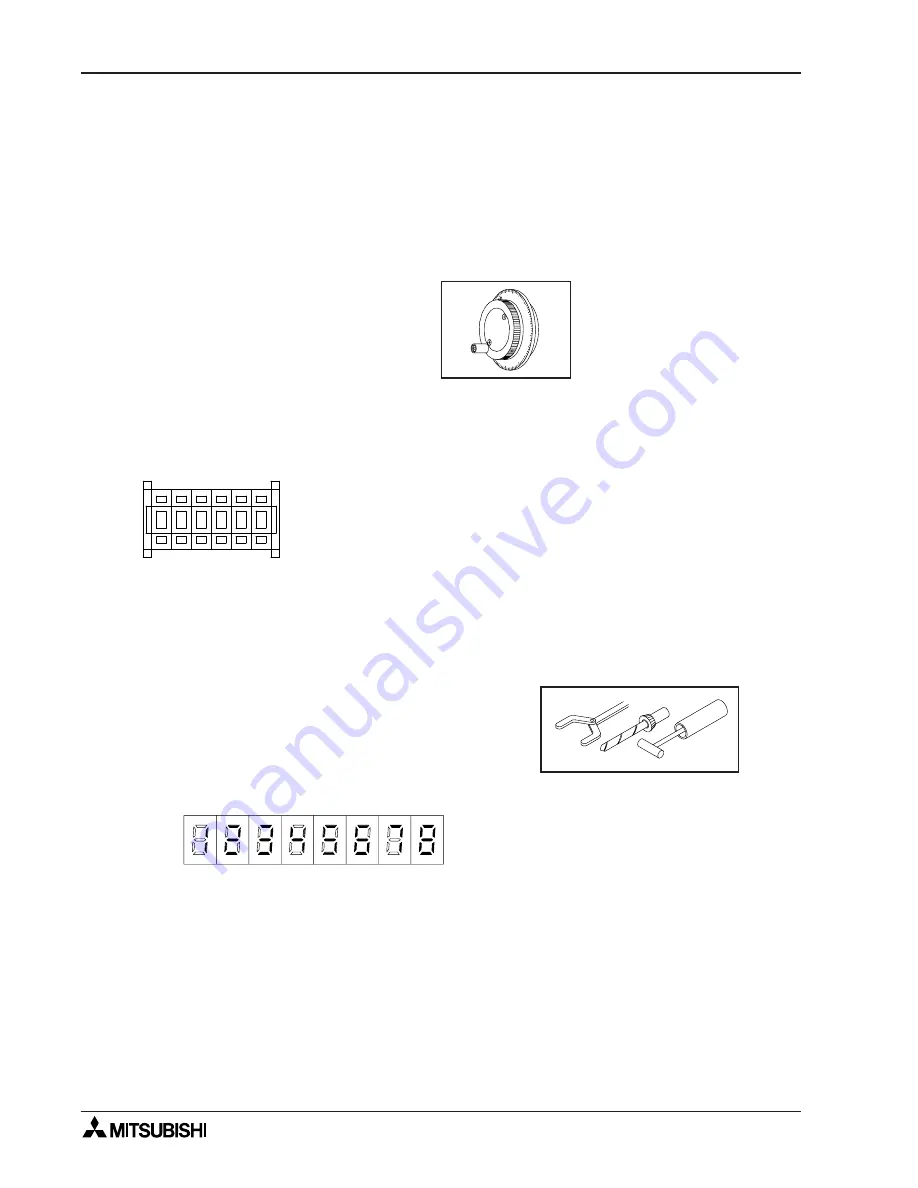

FX-10GM POSITIONING CONTROLLER

Units for general I/O connection

For the general I/Os of the positioning unit and the extension I/Os of the programmable

controller the following external units can be connected.

1)

Various input switches

The various input switches such as a push-button switch, limit switch, sensor,

etc. can be connected.

2)

Manual pulse generator

A p u l s e g e n e r a t o r c a n b e

connected to each axis, or one

p u l s e g e n e r a t o r c a n b e

connected to both axes and

switched between them. The

manual pulse generators used

must be an open collector output

type.

General input/extension input

1)

Input from the digital switch

3)

Interrupt input

T h e i n p u t f r o m t h e

manual pulse generator

can be used as control

i n p u t f o r i n t e r r u p t

positioning control by

switching the line.

90

0

10

60

70

80

• Up to 6 digits are

possible with the FX-

10GM. Use with a

programmable cont-

roller for more digits.

1 2 3 4 5 6

+

-

+

-

+

-

+

-

+

-

+

-

Various data settings can be fetched

through connections that save wiring,

either by a direct connection method

or by multiplexing input/outputs.

General output/extension output

1)

Auxiliary equipment control output

The ON/OFF control outputs for

various auxiliary equipment are

generated by M code signals (2-digit

BCD) or a direct program.

2)

Seven-segment display

Various setting data and statuses,

and present value, can be displayed

through connections that save wiring,

either by a direct connection method

or by multiplexing outputs.

The following data can be set using

direct specification instructions.

• Target position

• Speed

• Center coordinates of circular arc

• Radius of circular arc

• Various parameters and control constants

a) Current position display:

8 digits maximum for each axis.

b) The line No. being executed, the set

speed, the present dwell value, various

parameters and the status can be read

and displayed.

• Up to 2 digits are possible with the

FX-10GM. Use with a programmable

controller for more digits.

•

The positioning control command inputs and the drive unit connection are enabled

via dedicated I/O.