13

13-59

•

If it does not move smoothly, check for an installed condition of

the accelerator control cable and accelerator link. (See “EN-

GINE CONTROL”.)

2. Inspection of Fuel Leakage

•

Check if there is no fuel leakage from the fuel tank, fuel filter, supply pump, common rail, injector and fuel piping.

If there is a fuel leakage, replace the pipe or hose and tighten to the specified torque. If fuel leaks from joint, re-

tighten the bolts, nuts and clamps to the specified torque. (See later section.)

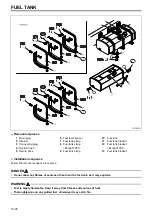

3. Inspection of Injection Pipe and Fuel Pipe Mounting Clamp

Tightening torque (Unit: N·m {kgf·m})

•

Visually check the clamp appearance and make sure there is no

cracks or damages at the rubber part of the clamps.

•

If there is any abnormality, replace the clamp.

•

Check for looseness in the clamp mounting bolt or nuts. If there

is looseness, tighten the bolts and nuts to the specified torque.

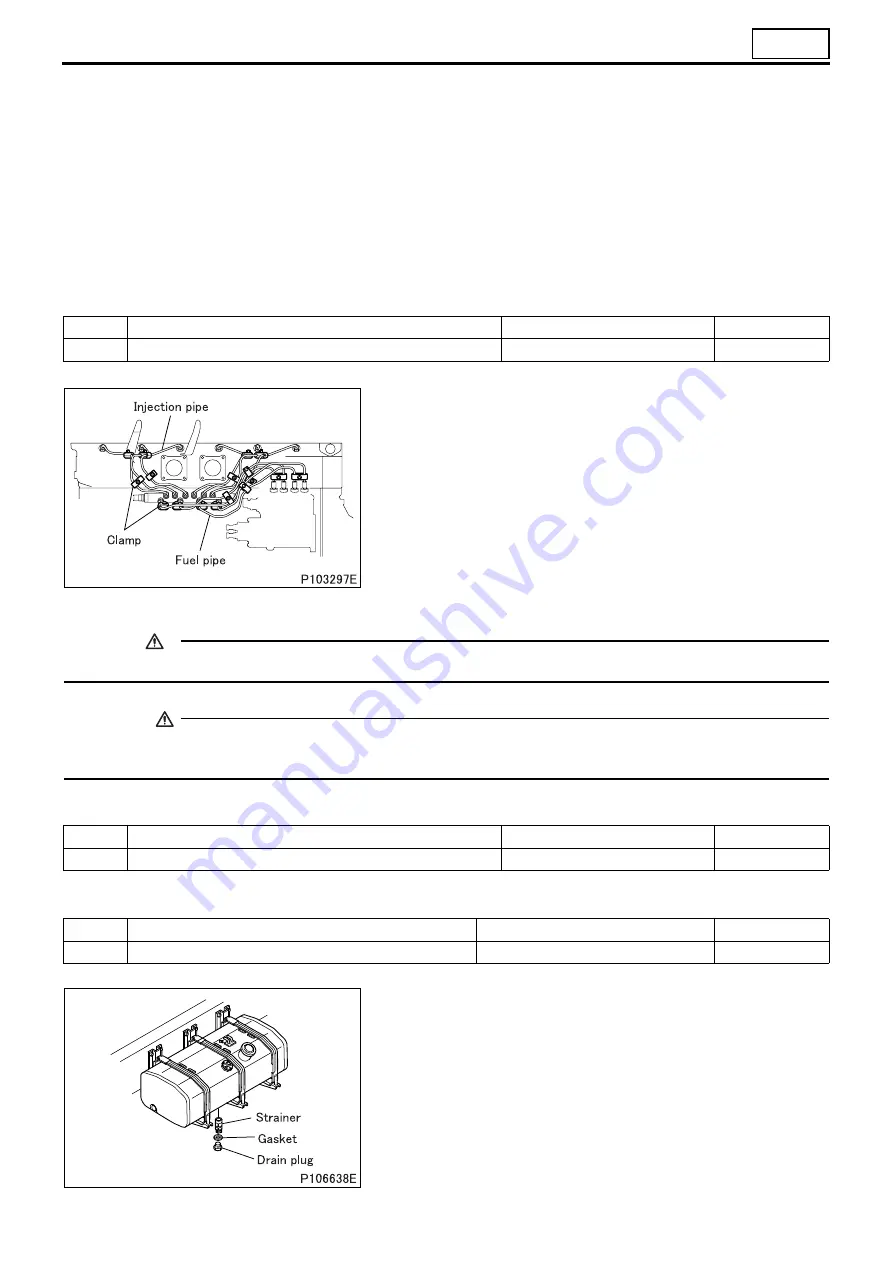

4. Draining of Deposit in Fuel Tank

DANGER

• Do not allow any flames or sources of heat near the fuel tank, as it may explode.

WARNING

• Fuel is highly flammable. Keep it away from flames and sources of heat.

• Thoroughly wipe up any spilled fuel, otherwise it may catch fire.

Tightening torque (Unit: N·m {kgf·m})

Lubricant and/or sealant

[Removal]

•

Drain the deposit in the fuel tank by removing the drain plug,

gasket and strainer from the fuel tank.

[Installation]

•

Install the strainer and gasket to the fuel tank. Tighten the drain

plug to the specified torque.

Mark

Parts to be tightened

Tightening torque

Remarks

–

Bolt or nut (clamp mounting)

17.6 to 21.6 {1.8 to 2.2}

–

Mark

Parts to be tightened

Tightening torque

Remarks

–

Drain plug

127 {13}

Sealant

Location

Points of application

Specified lubricant and/or sealant

Quantity

–

Seat surface of drain plug

Seal end No. 22

As required

Summary of Contents for 6M70

Page 29: ...M E M O 11 19 11 ...

Page 35: ...M E M O 11 25 11 ...

Page 36: ...11 26 MITSUBISHI 6M70 ROCKER COVER ROCKER AND SHAFT ...

Page 40: ...11 30 MITSUBISHI 6M70 CAMSHAFT AND ROCKER CASE ...

Page 47: ...M E M O 11 37 11 ...

Page 48: ...11 38 MITSUBISHI 6M70 CYLINDER HEAD AND VALVE MECHANISM ...

Page 63: ...M E M O 11 53 11 ...

Page 71: ...M E M O 11 61 11 ...

Page 77: ...M E M O 11 67 11 ...

Page 81: ...M E M O 11 71 11 ...

Page 98: ...11 88 MITSUBISHI 6M70 CRANKSHAFT AND CRANKCASE ...

Page 127: ...M E M O 12 21 12 ...

Page 129: ...M E M O 12 23 12 ...

Page 135: ...M E M O 13 3 13 ...

Page 138: ...13 6 1 1 Mitsubishi 6M70 Supply pump STRUCTURE AND OPERATION ...

Page 150: ...13 18 10 Electronic control unit connection diagram STRUCTURE AND OPERATION ...

Page 151: ...13 13 19 ...

Page 155: ...M E M O 13 23 13 ...

Page 185: ...M E M O 13 53 13 ...

Page 189: ...M E M O 13 57 13 ...

Page 205: ...M E M O 13 73 13 ...

Page 211: ...M E M O 13 79 13 ...

Page 215: ...M E M O 13 83 13 ...

Page 219: ...M E M O 13 87 13 ...

Page 225: ...M E M O 13 93 13 ...

Page 226: ...13 94 INSTALLED LOCATIONS OF PARTS ...

Page 227: ...13 13 95 ...

Page 228: ...13 96 INSTALLED LOCATIONS OF PARTS ...

Page 229: ...13 13 97 ...

Page 230: ...13 98 INSTALLED LOCATIONS OF PARTS ...

Page 231: ...13 13 99 ...

Page 232: ...13 100 MITSUBISHI 6M70 INSTALLED LOCATIONS OF PARTS ...

Page 233: ...13 13 101 ...

Page 234: ...13 102 ELECTRIC CIRCUIT DIAGRAM ...

Page 235: ...13 13 103 ...

Page 236: ...13 104 ELECTRIC CIRCUIT DIAGRAM ...

Page 237: ...13 13 105 ...

Page 238: ...13 106 ELECTRIC CIRCUIT DIAGRAM ...

Page 241: ...14 14 3 1 Mitsubishi 6M70 Cooling System Flow of Coolant STRUCTURE AND OPERATION ...

Page 252: ...14 14 Periphery of Engine DISCONNECTION AND CONNECTION OF HOSES AND PIPES ...

Page 271: ...M E M O 14 33 14 ...

Page 286: ...M E M O 15 13 15 ...

Page 295: ...15 22 7 Installed Locations of Parts TURBOCHARGER CONTROL SYSTEM ...

Page 296: ...15 15 23 ...

Page 297: ...15 24 TURBOCHARGER CONTROL SYSTEM ...

Page 298: ...15 15 25 ...

Page 299: ...15 26 TURBOCHARGER CONTROL SYSTEM ...

Page 300: ...15 15 27 ...

Page 301: ...15 28 TURBOCHARGER CONTROL SYSTEM ...

Page 302: ...M E M O 15 29 15 ...

Page 303: ...15 30 8 Electric Circuit Diagram TURBOCHARGER CONTROL SYSTEM ...

Page 304: ...15 15 31 ...

Page 305: ...15 32 TURBOCHARGER CONTROL SYSTEM ...

Page 306: ...M E M O 15 33 15 ...

Page 330: ...M E M O 15 57 15 ...

Page 340: ...17 6 1 3 Electronic control unit connection diagram STRUCTURE AND OPERATION ...

Page 343: ...M E M O 17 9 17 ...

Page 351: ...M E M O 17 17 17 ...

Page 352: ...17 18 8 Installed Locations of Parts EXHAUST GAS RECIRCULATION SYSTEM ...

Page 353: ...17 17 19 ...

Page 354: ...17 20 EXHAUST GAS RECIRCULATION SYSTEM ...

Page 355: ...17 17 21 ...

Page 356: ...17 22 EXHAUST GAS RECIRCULATION SYSTEM ...

Page 357: ...17 17 23 ...

Page 358: ...17 24 9 Electric Circuit Diagram EXHAUST GAS RECIRCULATION SYSTEM ...

Page 359: ...17 17 25 ...

Page 360: ...17 26 MITSUBISHI 6M70 EGR VALVE EGR MAGNETIC VALVE EGR PIPE AND EGR COOLER ...