11

11-15

•

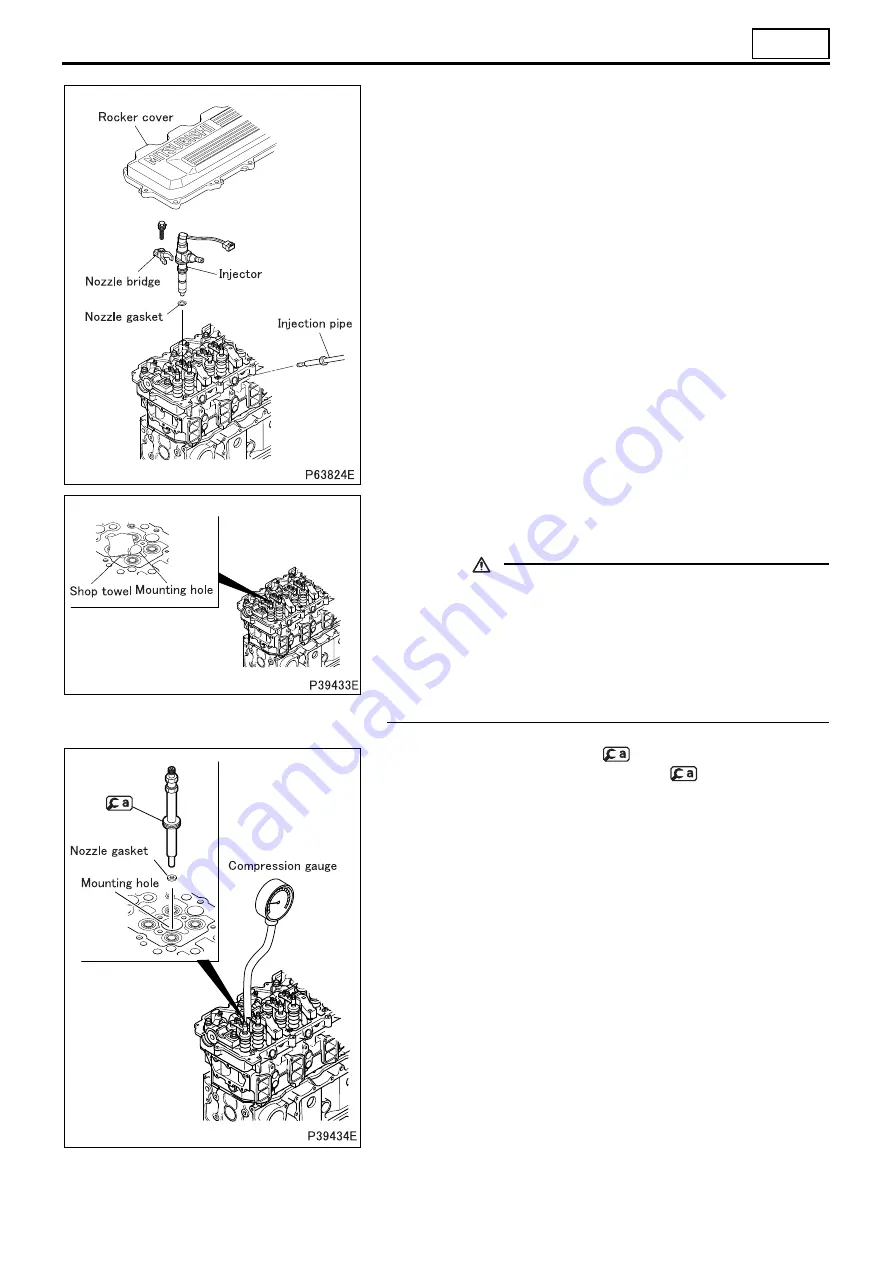

Remove all the injectors. (See Gr13.)

•

Cover the injector mounting holes with shop towels or other sim-

ilar cloth. Crank the engine using the starter. Ensure that no for-

eign matter is attached on the shop towels.

CAUTION

• If cracks or any other damage are evident in the cylinders,

this means that the coolant, engine oil or fuel, or other sub-

stances, has entered the cylinders. If this is the case, it is

extremely dangerous to crank the engine as these sub-

stances will gush out at high temperature from the injector

mounting holes. Stay away from the engine when cranking

it.

•

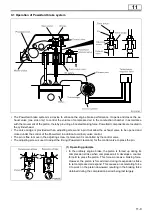

Attach the nozzle gasket and

to one of the mounting holes.

Then, connect a compression gauge to

.

•

Crank the engine and measure the compression pressure.

•

Measure the compression pressure for all the cylinders one after

another. Determine the compression pressure difference be-

tween the cylinders.

•

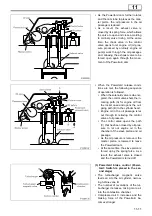

If the compression pressure is below the limit or the pressure dif-

ference between each cylinder is not within the limit, pour a

small amount of engine oil into the corresponding mounting hole

and measure the compression pressure again.

•

If the compression pressure increases, the piston rings and

inner surfaces of cylinder may be badly worn or otherwise

damaged.

•

If the compression pressure remains unchanged, there may

be seizure in the valves, the valves may be incorrectly seated

or the cylinder head gasket may be defective.

•

Install the injector. (See Gr13.)

•

Install the rocker cover and the gasket. (See “ROCKER COV-

ER, ROCKER AND SHAFT”.)

Summary of Contents for 6M70

Page 29: ...M E M O 11 19 11 ...

Page 35: ...M E M O 11 25 11 ...

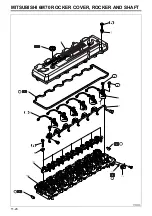

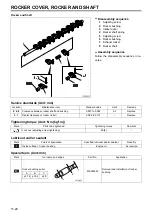

Page 36: ...11 26 MITSUBISHI 6M70 ROCKER COVER ROCKER AND SHAFT ...

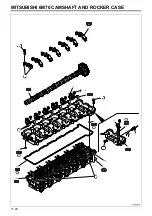

Page 40: ...11 30 MITSUBISHI 6M70 CAMSHAFT AND ROCKER CASE ...

Page 47: ...M E M O 11 37 11 ...

Page 48: ...11 38 MITSUBISHI 6M70 CYLINDER HEAD AND VALVE MECHANISM ...

Page 63: ...M E M O 11 53 11 ...

Page 71: ...M E M O 11 61 11 ...

Page 77: ...M E M O 11 67 11 ...

Page 81: ...M E M O 11 71 11 ...

Page 98: ...11 88 MITSUBISHI 6M70 CRANKSHAFT AND CRANKCASE ...

Page 127: ...M E M O 12 21 12 ...

Page 129: ...M E M O 12 23 12 ...

Page 135: ...M E M O 13 3 13 ...

Page 138: ...13 6 1 1 Mitsubishi 6M70 Supply pump STRUCTURE AND OPERATION ...

Page 150: ...13 18 10 Electronic control unit connection diagram STRUCTURE AND OPERATION ...

Page 151: ...13 13 19 ...

Page 155: ...M E M O 13 23 13 ...

Page 185: ...M E M O 13 53 13 ...

Page 189: ...M E M O 13 57 13 ...

Page 205: ...M E M O 13 73 13 ...

Page 211: ...M E M O 13 79 13 ...

Page 215: ...M E M O 13 83 13 ...

Page 219: ...M E M O 13 87 13 ...

Page 225: ...M E M O 13 93 13 ...

Page 226: ...13 94 INSTALLED LOCATIONS OF PARTS ...

Page 227: ...13 13 95 ...

Page 228: ...13 96 INSTALLED LOCATIONS OF PARTS ...

Page 229: ...13 13 97 ...

Page 230: ...13 98 INSTALLED LOCATIONS OF PARTS ...

Page 231: ...13 13 99 ...

Page 232: ...13 100 MITSUBISHI 6M70 INSTALLED LOCATIONS OF PARTS ...

Page 233: ...13 13 101 ...

Page 234: ...13 102 ELECTRIC CIRCUIT DIAGRAM ...

Page 235: ...13 13 103 ...

Page 236: ...13 104 ELECTRIC CIRCUIT DIAGRAM ...

Page 237: ...13 13 105 ...

Page 238: ...13 106 ELECTRIC CIRCUIT DIAGRAM ...

Page 241: ...14 14 3 1 Mitsubishi 6M70 Cooling System Flow of Coolant STRUCTURE AND OPERATION ...

Page 252: ...14 14 Periphery of Engine DISCONNECTION AND CONNECTION OF HOSES AND PIPES ...

Page 271: ...M E M O 14 33 14 ...

Page 286: ...M E M O 15 13 15 ...

Page 295: ...15 22 7 Installed Locations of Parts TURBOCHARGER CONTROL SYSTEM ...

Page 296: ...15 15 23 ...

Page 297: ...15 24 TURBOCHARGER CONTROL SYSTEM ...

Page 298: ...15 15 25 ...

Page 299: ...15 26 TURBOCHARGER CONTROL SYSTEM ...

Page 300: ...15 15 27 ...

Page 301: ...15 28 TURBOCHARGER CONTROL SYSTEM ...

Page 302: ...M E M O 15 29 15 ...

Page 303: ...15 30 8 Electric Circuit Diagram TURBOCHARGER CONTROL SYSTEM ...

Page 304: ...15 15 31 ...

Page 305: ...15 32 TURBOCHARGER CONTROL SYSTEM ...

Page 306: ...M E M O 15 33 15 ...

Page 330: ...M E M O 15 57 15 ...

Page 340: ...17 6 1 3 Electronic control unit connection diagram STRUCTURE AND OPERATION ...

Page 343: ...M E M O 17 9 17 ...

Page 351: ...M E M O 17 17 17 ...

Page 352: ...17 18 8 Installed Locations of Parts EXHAUST GAS RECIRCULATION SYSTEM ...

Page 353: ...17 17 19 ...

Page 354: ...17 20 EXHAUST GAS RECIRCULATION SYSTEM ...

Page 355: ...17 17 21 ...

Page 356: ...17 22 EXHAUST GAS RECIRCULATION SYSTEM ...

Page 357: ...17 17 23 ...

Page 358: ...17 24 9 Electric Circuit Diagram EXHAUST GAS RECIRCULATION SYSTEM ...

Page 359: ...17 17 25 ...

Page 360: ...17 26 MITSUBISHI 6M70 EGR VALVE EGR MAGNETIC VALVE EGR PIPE AND EGR COOLER ...