00-28

•

Use specified bolts and nuts. Tighten them to the torques shown below as appropriate, unless otherwise speci-

fied.

•

Threads and bearing surfaces shall be dry.

•

If the mating nut and bolt (or stud bolt) are different in level of strength, tighten them to the torque specified for the

bolt.

Hexagon Head Bolts and Stud Bolts (Unit: N·m {kgf·m})

Hexagon Head Flange Bolts (Unit: N·m {kgf·m})

Strength

4T

7T

8T

Identification

symbol

Nominal

diameter

(stud)

(stud)

(stud)

M5

2 to 3

{0.2 to 0.3}

–

4 to 6

{0.4 to 0.6}

–

5 to 7

{0.5 to 0.7}

–

M6

4 to 6

{0.4 to 0.6}

–

7 to 10

{0.7 to 1.0}

–

8 to 12

{0.8 to 1.2}

–

M8

9 to 13

{0.9 to 1.3}

–

16 to 24

{1.7 to 2.5}

–

19 to 28

{2.0 to 2.9}

–

M10

18 to 27

{1.8 to 2.7}

17 to 25

{1.8 to 2.6}

34 to 50

{3.5 to 5.1}

32 to 48

{3.3 to 4.9}

45 to 60

{4.5 to 6.0}

37 to 55

{3.8 to 5.7}

M12

34 to 50

{3.4 to 5.1}

31 to 45

{3.1 to 4.6}

70 to 90

{7.0 to 9.5}

65 to 85

{6.5 to 8.5}

80 to 105

{8.5 to 11}

75 to 95

{7.5 to 10}

M14

60 to 80

{6.0 to 8.0}

55 to 75

{5.5 to 7.5}

110 to 150

{11 to 15}

100 to 140

{11 to 14}

130 to 170

{13 to 17}

120 to 160

{12 to 16}

M16

90 to 120

{9 to 12}

90 to 110

{9 to 11}

170 to 220

{17 to 23}

160 to 210

{16 to 21}

200 to 260

{20 to 27}

190 to 240

{19 to 25}

M18

130 to 170

{14 to 18}

120 to 150

{12 to 16}

250 to 330

{25 to 33}

220 to 290

{23 to 30}

290 to 380

{30 to 39}

250 to 340

{26 to 35}

M20

180 to 240

{19 to 25}

170 to 220

{17 to 22}

340 to 460

{35 to 47}

310 to 410

{32 to 42}

400 to 530

{41 to 55}

360 to 480

{37 to 49}

M22

250 to 330

{25 to 33}

230 to 300

{23 to 30}

460 to 620

{47 to 63}

420 to 560

{43 to 57}

540 to 720

{55 to 73}

490 to 650

{50 to 67}

M24

320 to 430

{33 to 44}

290 to 380

{29 to 39}

600 to 810

{62 to 83}

540 to 720

{55 to 73}

700 to 940

{72 to 96}

620 to 830

{63 to 85}

Strength

4T

7T

8T

Identification

symbol

Nominal

diameter

M6

4 to 6

{0.4 to 0.6}

–

8 to 12

{0.8 to 1.2}

–

10 to 14

{1.0 to 1.4}

–

M8

10 to 15

{1.0 to 1.5}

–

19 to 28

{2.0 to 2.9}

–

22 to 33

{2.3 to 3.3}

–

M10

21 to 31

{2.1 to 3.1}

20 to 29

{2.0 to 3.0}

45 to 55

{4.5 to 5.5}

37 to 54

{3.8 to 5.6}

50 to 65

{5.0 to 6.5}

50 to 60

{5.0 to 6.5}

M12

38 to 56

{3.8 to 5.5}

35 to 51

{3.5 to 5.2}

80 to 105

{8.0 to 10.5}

70 to 95

{7.5 to 9.5}

90 to 120

{9 to 12}

85 to 110

{8.5 to 11}

TABLE OF STANDARD TIGHTENING TORQUES

Summary of Contents for 6M70

Page 29: ...M E M O 11 19 11 ...

Page 35: ...M E M O 11 25 11 ...

Page 36: ...11 26 MITSUBISHI 6M70 ROCKER COVER ROCKER AND SHAFT ...

Page 40: ...11 30 MITSUBISHI 6M70 CAMSHAFT AND ROCKER CASE ...

Page 47: ...M E M O 11 37 11 ...

Page 48: ...11 38 MITSUBISHI 6M70 CYLINDER HEAD AND VALVE MECHANISM ...

Page 63: ...M E M O 11 53 11 ...

Page 71: ...M E M O 11 61 11 ...

Page 77: ...M E M O 11 67 11 ...

Page 81: ...M E M O 11 71 11 ...

Page 98: ...11 88 MITSUBISHI 6M70 CRANKSHAFT AND CRANKCASE ...

Page 127: ...M E M O 12 21 12 ...

Page 129: ...M E M O 12 23 12 ...

Page 135: ...M E M O 13 3 13 ...

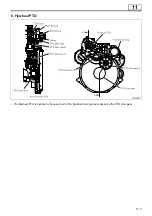

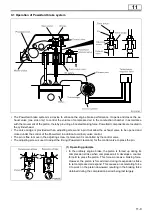

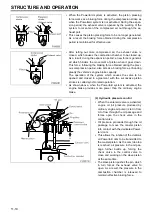

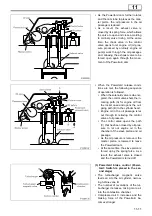

Page 138: ...13 6 1 1 Mitsubishi 6M70 Supply pump STRUCTURE AND OPERATION ...

Page 150: ...13 18 10 Electronic control unit connection diagram STRUCTURE AND OPERATION ...

Page 151: ...13 13 19 ...

Page 155: ...M E M O 13 23 13 ...

Page 185: ...M E M O 13 53 13 ...

Page 189: ...M E M O 13 57 13 ...

Page 205: ...M E M O 13 73 13 ...

Page 211: ...M E M O 13 79 13 ...

Page 215: ...M E M O 13 83 13 ...

Page 219: ...M E M O 13 87 13 ...

Page 225: ...M E M O 13 93 13 ...

Page 226: ...13 94 INSTALLED LOCATIONS OF PARTS ...

Page 227: ...13 13 95 ...

Page 228: ...13 96 INSTALLED LOCATIONS OF PARTS ...

Page 229: ...13 13 97 ...

Page 230: ...13 98 INSTALLED LOCATIONS OF PARTS ...

Page 231: ...13 13 99 ...

Page 232: ...13 100 MITSUBISHI 6M70 INSTALLED LOCATIONS OF PARTS ...

Page 233: ...13 13 101 ...

Page 234: ...13 102 ELECTRIC CIRCUIT DIAGRAM ...

Page 235: ...13 13 103 ...

Page 236: ...13 104 ELECTRIC CIRCUIT DIAGRAM ...

Page 237: ...13 13 105 ...

Page 238: ...13 106 ELECTRIC CIRCUIT DIAGRAM ...

Page 241: ...14 14 3 1 Mitsubishi 6M70 Cooling System Flow of Coolant STRUCTURE AND OPERATION ...

Page 252: ...14 14 Periphery of Engine DISCONNECTION AND CONNECTION OF HOSES AND PIPES ...

Page 271: ...M E M O 14 33 14 ...

Page 286: ...M E M O 15 13 15 ...

Page 295: ...15 22 7 Installed Locations of Parts TURBOCHARGER CONTROL SYSTEM ...

Page 296: ...15 15 23 ...

Page 297: ...15 24 TURBOCHARGER CONTROL SYSTEM ...

Page 298: ...15 15 25 ...

Page 299: ...15 26 TURBOCHARGER CONTROL SYSTEM ...

Page 300: ...15 15 27 ...

Page 301: ...15 28 TURBOCHARGER CONTROL SYSTEM ...

Page 302: ...M E M O 15 29 15 ...

Page 303: ...15 30 8 Electric Circuit Diagram TURBOCHARGER CONTROL SYSTEM ...

Page 304: ...15 15 31 ...

Page 305: ...15 32 TURBOCHARGER CONTROL SYSTEM ...

Page 306: ...M E M O 15 33 15 ...

Page 330: ...M E M O 15 57 15 ...

Page 340: ...17 6 1 3 Electronic control unit connection diagram STRUCTURE AND OPERATION ...

Page 343: ...M E M O 17 9 17 ...

Page 351: ...M E M O 17 17 17 ...

Page 352: ...17 18 8 Installed Locations of Parts EXHAUST GAS RECIRCULATION SYSTEM ...

Page 353: ...17 17 19 ...

Page 354: ...17 20 EXHAUST GAS RECIRCULATION SYSTEM ...

Page 355: ...17 17 21 ...

Page 356: ...17 22 EXHAUST GAS RECIRCULATION SYSTEM ...

Page 357: ...17 17 23 ...

Page 358: ...17 24 9 Electric Circuit Diagram EXHAUST GAS RECIRCULATION SYSTEM ...

Page 359: ...17 17 25 ...

Page 360: ...17 26 MITSUBISHI 6M70 EGR VALVE EGR MAGNETIC VALVE EGR PIPE AND EGR COOLER ...