Chapter 9 Setup

9–17

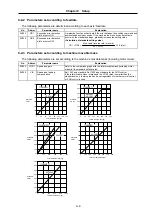

9-3-4 Setting the parallel drive system

When driving the linear motor with a parallel drive system, confirm that the following parameters are

correctly set for the (1), (2) 2-scale 2-motor (2-amplifier) control or (3) 1-scale 2-motor (2-amplifier)

control method. If incorrectly set, correct the setting and reboot the CNC power supply.

When using a parallel drive system, do not simultaneously DC excite the master side and slave side.

When carrying out DC excitation of either axis, make sure that current is not flowing to the other axis.

No. Abbrev.

Parameter

name

Details

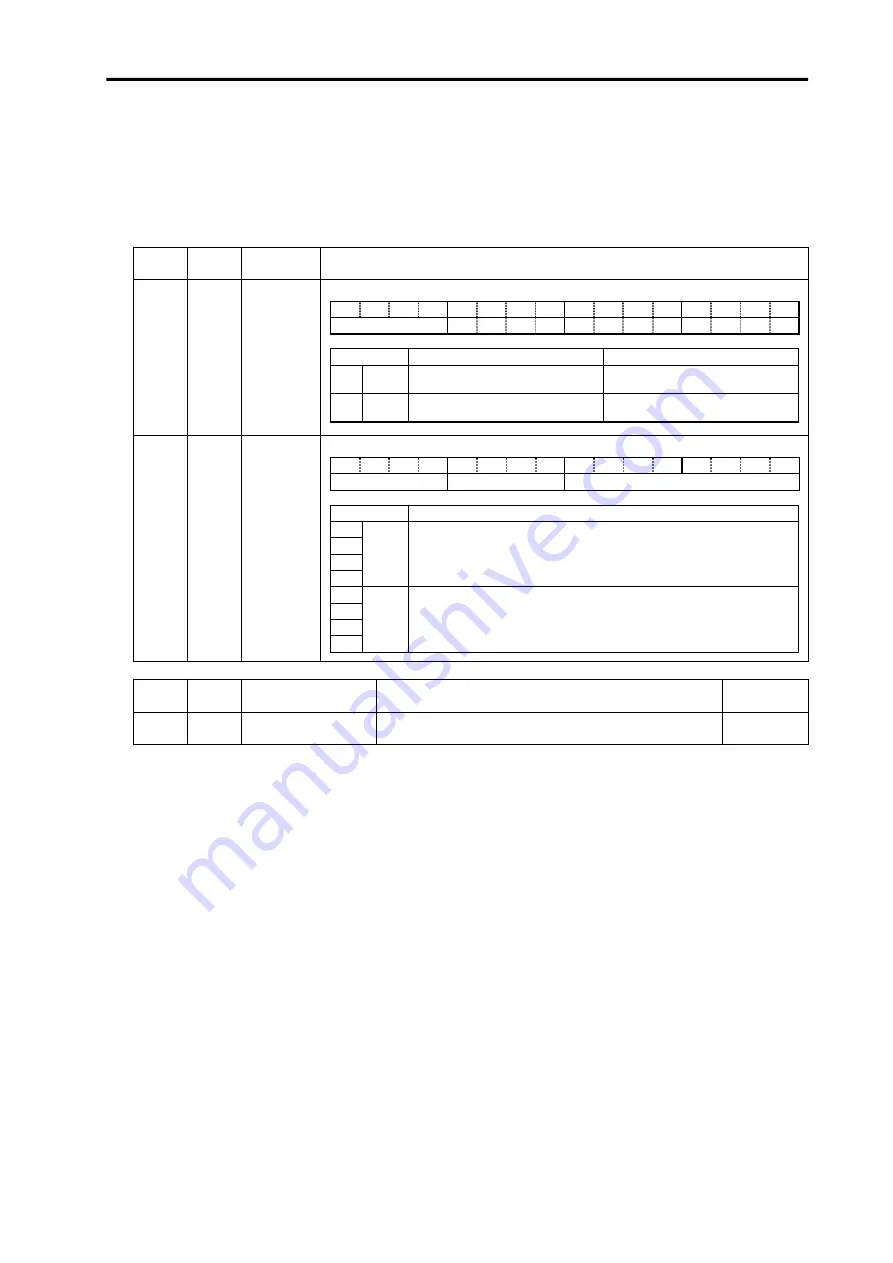

SV017 SPEC Servo

specifica-tion

s

This is a HEX setting parameter. Set this as follows according to the servo specification.

SV025 MTYP Motor/

detector type

This is a HEX setting parameter. Set this as follows according to the detector type.

No. Abbrev. Parameter

name

Explanation

Setting range

(Unit)

SV028

MSFT

Pole shift amount

Set the pole shift amount

–30000 to

30000 (µm)

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

spm drvall

drvup

mpt3

mp

abs

vmh

vdir

fdir

seqh

dfbx

vdir2

bit

Meaning when "0" is set

Meaning when "1" is set

4

fdir

Main side (CN2) feedback forward

polarity

Main side (CN2) feedback reverse

polarity

0

vdir2

Sub side (CN3) feedback forward

polarity

Sub side (CN3) feedback reverse

polarity

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

pen ent

mtyp

bit Details

8

9

10

11

ent

Set the position detector type

(Refer to 9-2-1 (6) Detector type list)

12

13

14

15

pen

Set the speed detector type.

(Refer to 9-2-1 (6) Detector type list)