33

4 PRECAUTIONS FOR USE OF THE INVERTER

The FR-E800 series inverter is a highly reliable product, but incorrect peripheral circuit making or operation/handling

method may shorten the product life or damage the product. Before starting operation, always recheck the following

points.

Checkpoint

Countermeasure

Crimp terminals are insulated.

Use crimp terminals with insulation sleeves to wire the power supply and the motor.

The wiring between the power

supply (terminals R/L1, S/L2, T/

L3) and the motor (terminals U, V,

W) is correct.

Application of power to the output terminals (U, V, W) of the inverter will damage the inverter. Never

perform such wiring.

No wire offcuts are left from the

time of wiring.

Wire offcuts can cause a fault, failure, or malfunction. Always keep the inverter clean. When drilling

mounting holes in an enclosure etc., take caution not to allow chips and other foreign matter to enter

the inverter.

The main circuit cable gauge is

correctly selected.

Use an appropriate cable gauge to suppress the voltage drop to 2% or less. If the wiring distance is

long between the inverter and motor, a voltage drop in the main circuit will cause the motor torque to

decrease especially during the output of a low frequency.

The total wiring length is within

the specified length.

Keep the total wiring length within the specified length. In long distance wiring, charging currents

due to stray capacitance in the wiring may degrade the fast-response current limit operation or

cause the equipment on the inverter's output side to malfunction. Pay attention to the total wiring

length.

Countermeasures are taken

against EMI.

The input/output (main circuit) of the inverter includes high frequency components, which may

interfere with the communication devices (such as AM radios) used near the inverter. Connect radio

noise filters or EMC filters on the input side of the inverter to minimize interference.

On the inverter's output side,

there is no power factor

correction capacitor, surge

suppressor, or radio noise filter

installed.

Doing so will shut off the inverter output or damage the capacitor or surge suppressor. If any of the

above devices is connected, immediately remove it.

When performing an inspection

or rewiring on the product that

has been energized, the operator

has waited long enough after

shutting off the power supply.

For a short time after the power-OFF, a high voltage remains in the smoothing capacitor, and it is

dangerous. Before performing an inspection or rewiring, wait 10 minutes or longer after the power

supply turns OFF, then confirm that the voltage across the main circuit terminals P/+ and N/- of the

inverter is low enough using a digital multimeter, etc.

The inverter's output side has no

short circuit or ground fault

occurring.

A short circuit or ground fault on the inverter's output side may damage the inverter module.

Fully check the insulation resistance of the circuit prior to inverter operation since repeated short

circuits caused by peripheral circuit inadequacy or an earth (ground) fault caused by wiring

inadequacy or reduced motor insulation resistance may damage the inverter module.

Fully check the to-earth (ground) insulation and phase-to-phase insulation of the inverter's output

side before power-ON. Especially for an old motor or use in hostile atmosphere, securely check the

motor insulation resistance, etc.

The circuit is not configured to

use the inverter's input-side

magnetic contactor to start/stop

the inverter frequently.

Since repeated inrush currents at power ON will shorten the life of the converter circuit, frequent

starts and stops of the magnetic contactor must be avoided. Turn ON or OFF the inverter's start

(STF/STR) signal to run or stop the inverter.

A mechanical brake is not

connected to terminals P/+ and

PR.

To terminals P/+ and PR, connect only an external brake resistor.

The voltage applied to the

inverter I/O signal circuits is

within the specifications.

Application of a voltage higher than the permissible voltage to the inverter I/O signal circuits or

opposite polarity may damage the I/O devices.

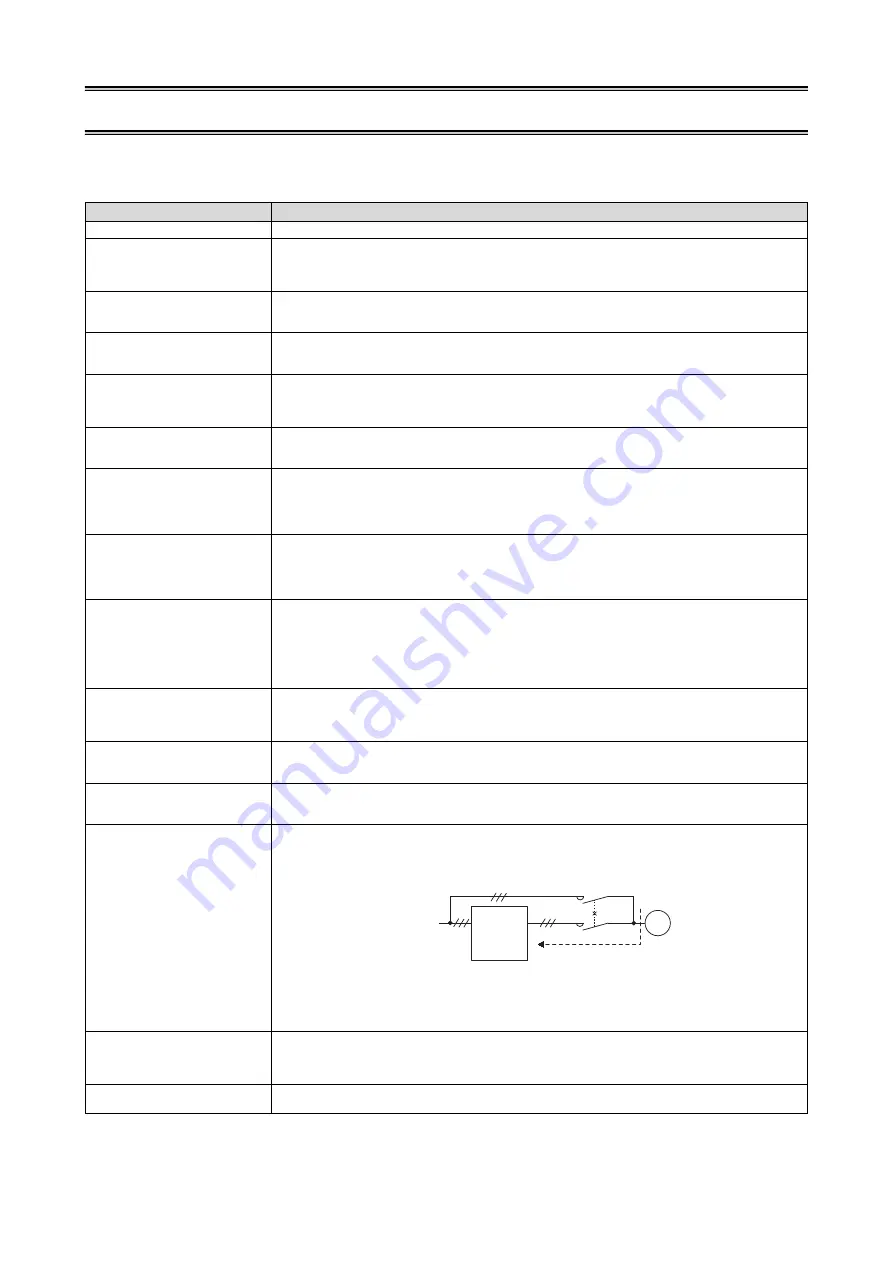

When using the electronic bypass

operation, electrical and

mechanical interlocks are

provided between the electronic

bypass contactors MC1 and

MC2.

When using a switching circuit as shown below, chattering due to misconfigured sequence or arc

generated at switching may allow undesirable current to flow in and damage the inverter. Miswiring

may also damage the inverter. (Note that a PM motor cannot be driven by the commercial power

supply.)

If switching to the commercial power supply operation while a failure such as an output short circuit

has occurred between the magnetic contactor MC2 and the motor, the damage may further spread.

If a failure has occurred between the MC2 and the motor, a protection circuit such as using the OH

signal input must be provided.

A countermeasure is provided for

power restoration after a power

failure.

If the machine must not be restarted when power is restored after a power failure, provide an MC on

the inverter's input side and also make up a sequence which will not switch ON the start signal. If the

start signal (start switch) remains ON after a power failure, the inverter will automatically restart as

soon as the power is restored.

For Vector control, the encoder is

properly installed.

The encoder must be directly connected to a motor shaft without any backlash. (Real sensorless

vector control or PM sensorless vector control does not require an encoder.)

MC2

MC1

U

V

W

R/L1

S/L2

T/L3

IM

Power

supply

Inverter

Undesirable current

Interlock

Summary of Contents for 800 Series

Page 10: ...4 INSTALLATION AND INSTRUCTIONS ...

Page 46: ...40 BASIC OPERATION ...

Page 64: ...58 INVERTER FAULT AND ALARM INDICATIONS ...

Page 70: ...64 SPECIFICATIONS ...