59

Version C

Mini-Cam

Proteus Lite

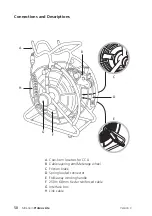

Cable Layering Arm

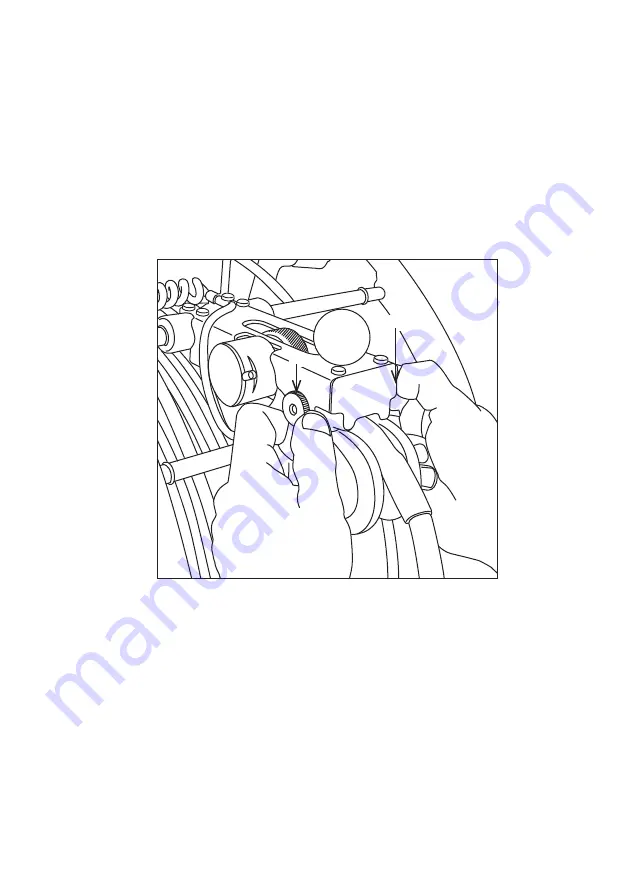

The RMPL250 features a manual cable layering arm which ensures smooth,

uninterrupted, tangle-free pay-out and rewinding of the 250 metres of 6.8mm

Kevlar

reinforced cable. The layering arm is designed to open easily for cleaning

and maintenance, a simple two-step procedure releases the rollers.

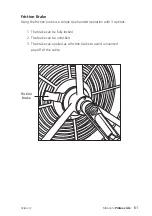

Cleaning and Maintenance

1

T o release the rollers for cleaning and maintenance, start by unscrewing the

t wo access pins (

A

).

A

A

Summary of Contents for Proteus Lite

Page 1: ...Original Instruction Manual Version C...

Page 2: ...2 Version C Mini Cam Proteus Lite...

Page 108: ...108 Version C Mini Cam Proteus Lite...

Page 112: ...112 Version C Mini Cam Proteus Lite...

Page 113: ...113 Version C Mini Cam Proteus Lite Notes...

Page 114: ...114 Version C Mini Cam Proteus Lite Notes...

Page 115: ......