78

7

−

19. Monitor mode

In the Monitor mode, the applied load on the strain gage applied transducer at present can be

displayed with the converted unit to mV/V.

For example, in case that the load cell is used, and its output value is unclear, apply actual load in

order to read the output value at the time of initial load application and also at the time of the

maximum load application by using the function and then make calibration with the obtained

value as a base.

●

The display value in the Monitor mode is a reference value.

The accuracy of display is 0.5 % approximately.

●

In the Monitor mode, the range which can be monitored is from

−

0.5 mV/V to 3.1 mV/V approximately.

●

When the

key is pressed with the load display of “FUNC”, the

display will change as the following arrow marks indicate at every

time the key is pressed. However, every time the

is pressed, the

display will change as the reverse direction of the following arrow

marks.

“FUNC”

→

“CCAL”

→

“ACAL”

→

“LCAL”

→

“ZERO”

→

“SPAN”

→

“TARE”

→

“CHEK”

→

“MONT”

→

“VCAL”

→

“VADJ”

→

“FUNC”

→

“CCAL”

・・・

(Hereinafter, over and over again.)

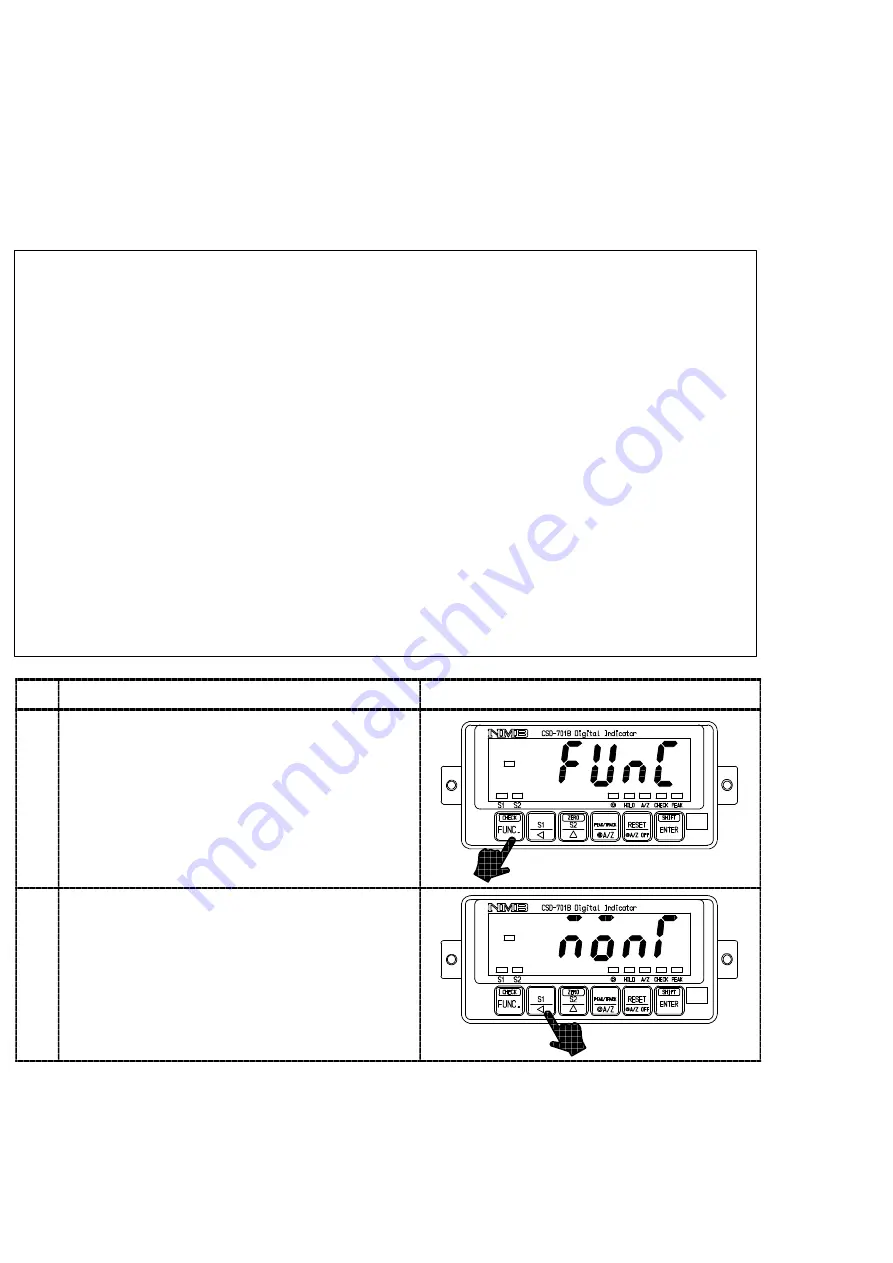

Procedures

1

Press the

key for one second.

The load display will show “FUNC”.

2

Press the

key 8 times.

The load display will change as “FUNC”

→

“CCAL”

→

“ACAL”

→

“LCAL”

→

“ZERO”

→

“SPAN”

→

“TARE”

→

“CHEK”

→

“MONT”.