- 46 -

Description of Ready Menu,

Continued

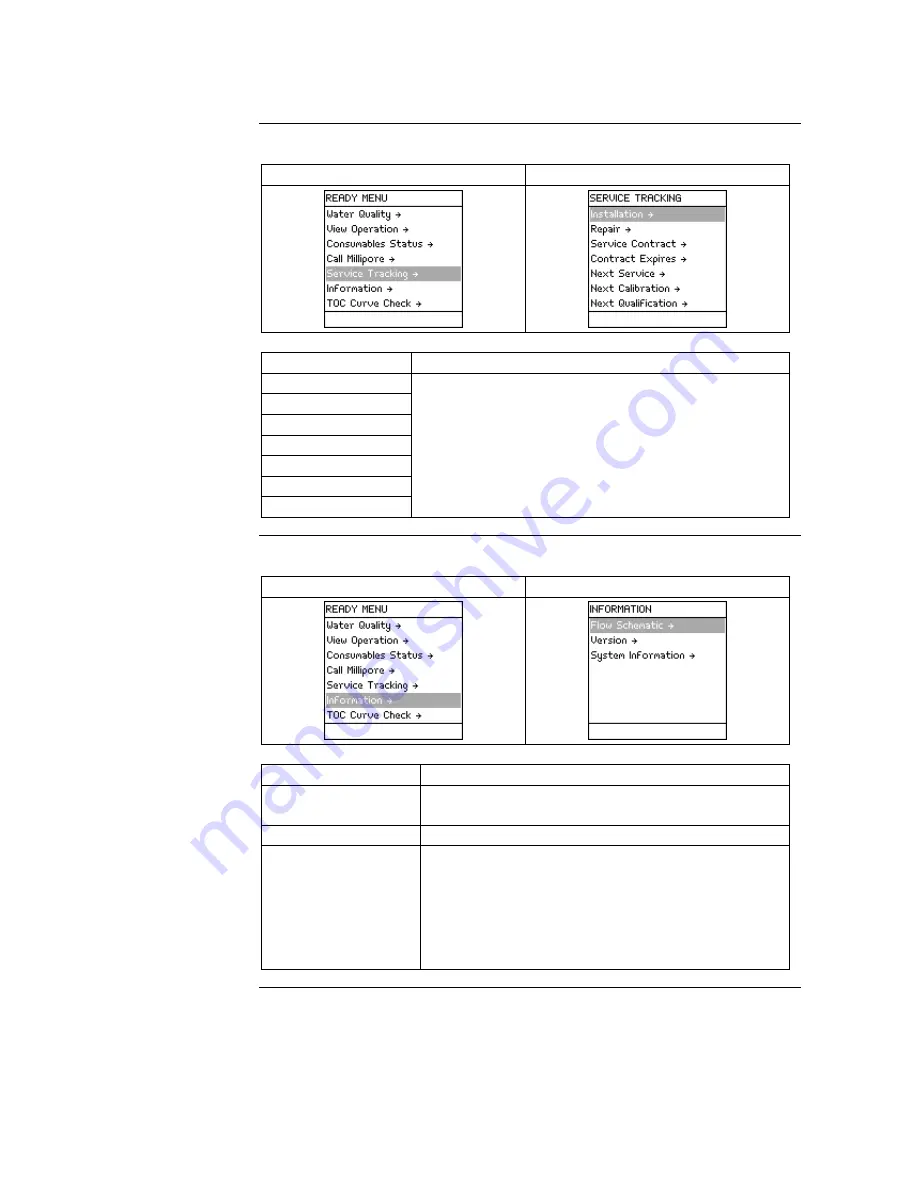

Service

Tracking

Diagram 1

Diagram 2

Item Description

Installation

Repair

Service Contract

Contract Expires

Next Service

Next Calibration

Next Qualification

View information that was inputted into the System

at time of servicing.

View information related to upcoming service.

NOTE:

This information is entered by a Millipore

Representative.

Information

Diagram 1

Diagram 2

Item Description

Flow Schematic

View information that explains the purpose of the

major components.

Version

View Software versions.

System Information

View:

•

System Type,

•

Catalogue Number,

•

Serial Number,

•

Installation Date, and

•

Manufacturing Date.

Summary of Contents for milli-q

Page 1: ...User Manual Milli Q Reference System...

Page 36: ...36 Software Map M a p...