8

Service Manual

www.microphase.eu

Dc

Notes during the assembly

Caution: during the wiring of the servodrive in the electrical box, make sure that do not enter leading

wires of copper or iron chips through the slits. Before performing the work cover the holes with a

piece of paper tape. Naturally finished work this tape is removed.

1.6

Ventilation

Positioning in the electrical box

Follow the instructions in the positioning of the servodrive in the electrical box.

- The drive is natural convection air flow cooled.

- To ensure the drive cooling and make the installation easier for the operator it must be installed

vertically leaving a free space of at least 25 mm on each side of the device. The converter must be

mounted vertically on the electrical box. In case you want to mount it horizontally, remove the cover.

- The electrical box must have suitably filtered air vents.

- Leave the necessary space both above and below the converters.

- Keep the drive from excessive mechanical vibration

1.5

Ambient conditions

N = Standard radiator (operating ambient temperature from 0 to 40°C)

N2 = Standard radiator (operating ambient temperature from 0 to 35°C)

V = Standard ra supplementary ventilation (operating ambient temperature from 0 to 45°C)

This servodrive are intended only for use in close locations. Ambient characteristics: operating tem-

perature from 0 to +40°C. Humidity limit s between 5% to 95% non condensing (Pollution degree 2 or

better). Supplementary ventilation may be requested in accordance to size. See the table below.

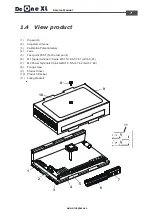

Cable duct

Cable duct

25

25

50

50

181,3

Conductive mounting panel (zinc coated)

Dimensions are

expressed in

millimeters.

SIZE

MODEL

2/4

4/8

7/14

10/20

14/28

20/40

30/60

12

N

N

N

N

N

N

N

65

N

N

N

N

N

N

V

145

N

N

N

N

N2

V

V

205

N

N

N

N2

V

V

V

305

N

N

N

N2

V

V

V