Copyright Meritor, Inc., 2021

MM-96147 / Revised 03-21

Page 88

(16579)

Printed in USA

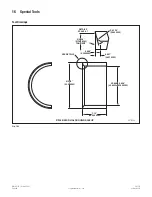

15 Driveline Balance Weight

Driveline Balance Weight

When re-balancing drivelines, proper driveline weights are

necessary. Meritor’s recommended practices for welding balance

weights are shown in Figure 15.1, Figure 15.2, Figure 15.3,

Figure 15.4 and Figure 15.5.

4017039a

WELD YOKE

BALANCE

WEIGHT

END YOKE

YOKE STYLE DRIVELINE/COUPLING

0.25” (6.35 MM)

RECOMMENDED

Fig. 15.1

Coupling shaft recommended balance weight placements on

tube

O.D.

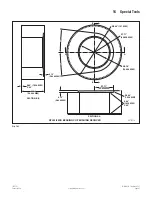

4017040a

SLIP YOKE

BALANCE

WEIGHT

SLIP YOKE CASTING/FORGING

0.25” (6.35 MM)

RECOMMENDED

Fig. 15.2

CAUTION

Slip yokes are cast iron material. If you are attaching a balance

weight to a slip yoke, proper welding procedures and materials

must be used when welding to cast iron materials. Failure to do

so may result in damage to the slip yoke.

4017041a

SLIP YOKE

BALANCE WEIGHT

YOKE STYLE DRIVELINE/SLIP

0.125” (3.175 MM)

RECOMMENDED

WELD

YOKE

Fig. 15.3

4017042a

CORRECT

NO STACKUPS

Fig. 15.4

INCORRECT

4017043b

CORRECT

Fig. 15.5