Copyright Meritor, Inc., 2021

MM-96147 / Revised 03-21

Page 39

(16579)

Printed in USA

5 RPL Series Permalube

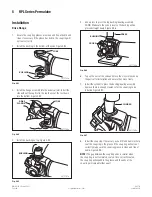

7. Install the new snap ring. Ensure it is seated all the way

around the groove. Use a drift and hammer if needed to seat it

in the groove all the way around. If the snap ring will not seat

correctly, make sure the snap ring groove is clean and free of

debris. Figure 5.87 and Figure 5.88.

NOTE:

The gap between the snap ring ends is smaller when the

snap ring is not completely seated. Once correctly seated, the snap

ring will expand in the groove and the ends of the snap ring will

spread further apart. Figure 5.89 and Figure 5.90.

4011761a

SNAP

RING

Fig. 5.87

4011762a

SNAP

RING

DRIFT

HAMMER

Fig. 5.88

4011773a

INCORRECTLY

SEATED

CORRECTLY

OEM SNAP RING

SEATED

0.450"

(11.4 MM)

MIN.

LESS THAN

0.450"

(11.4 MM)

Fig. 5.89

4011773b

INCORRECTLY

SEATED

CORRECTLY

SEATED

0.450"

(11.4 MM)

MIN.

LESS THAN

0.450"

(11.4 MM)

AFTERMARKET SNAP RING

Fig. 5.90

8. Rotate the drive fl ange 180 degrees.

9. Install the cylinder on the end and press DOWN until there

is snap ring clearance. Apply only the amount of pressure

needed to push the bearing down. Excess pressure may

cause damage to the snap ring installed on the other end.

Figure 5.91.

4011760a

CYLINDER

Fig. 5.91

10. Install the snap ring. Ensure it is seated all the way around

the groove. Use a drift and hammer if needed to seat it in

the groove all the way around. If the snap ring will not seat

correctly, make sure the snap ring groove is clean and free of

debris. Figure 5.92.

4011764a

SNAP

RING

Fig. 5.92