Copyright Meritor, Inc., 2021

MM-96147 / Revised 03-21

Page 52

(16579)

Printed in USA

8 Easy Service

Installation

Universal Joint

WARNING

Use a brass or synthetic mallet for assembly and disassembly

procedures. NEVER hit steel parts with a steel hammer. Pieces

of a part can break off. Serious personal injury and damage to

components can result.

CAUTION

Do not seat the bearing cups into the yoke saddle by tightening

down the bearing straps and capscrews. Uneven load

distribution, yoke bearing rotation, and damage to the straps and

yoke nibs can result.

NOTE:

To help ensure maximum driveline performance, do not

apply lubricant, grease, anti-seize compound, etc., to the yoke

saddles.

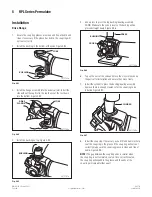

1. Install the universal joint cross into the yoke. Always use new

bolts and straps.

NOTE:

For easier installation, do not remove the wire that fastens

the bearing cups to the universal joint trunnion.

2. Install the bearing cups through the yoke bores and onto the

universal joint cross trunnions.

3. Tap the bearing cup lightly with a leather or rubber mallet to

seat the bearing cups into the yoke saddle.

NOTE:

Capscrews have a "lock patch" and can be hand-tightened

only two or three threads.

4. Hand-tighten the bearing capscrews. Use a torque wrench

to tighten the capscrews to the specifi ed torque. Refer to

Table D.

Driveline

1. Wipe off the yoke saddle.

NOTE:

Any time a universal joint is disconnected, new capscrews

must be used during reassembly.

2. Support the driveline. Install the bearing straps and new

capscrews onto the slip yoke end of the driveline.

NOTE:

Capscrews have a "lock patch" and can be hand-tightened

only two or three threads.

3. Hand-tighten the capscrews through the bearing strap into the

yoke.

4. Use a torque wrench to alternately tighten the capscrews

to Meritor’s driveline torque specifi cation. Refer to Table D.

Figure 8.10.

5. Repeat Step 1 through Step 3 to attach the weld yoke end of

the driveline to the vehicle.

4001851a

Fig. 8.10

Table D: Torque Specifi cations – Easy Service

Driveline

Series

"A" Inches

(mm)

Thread

Size

Inches

Torque Specs

lb-ft (Nm)

155T

4.97 (126.24)

3/8-24

40-60 (54-81)

16T

5.31 (134.87)

3/8-24

45-60 (61-81)

17T

6.19 (157.23)

1/2-20

115-135 (155-183)

176T

7.09 (180.08)

1/2-20

115-135 (155-183)

18T

7.63 (193.8)

1/2-20

115-135 (155-183)

“A”

dimension

between

yoke ears

determines

end yoke/

universal

joint series.

YOKE

GAUGE TOOL

“A”

Identifies

driveline series

4001855a