Servicing and Maintenance

Servicing

Servicing or maintenance of these unit must be carried out by experienced personnel with specific

training in refrigeration. Repeated check the safety devices and continuous cycling of control

components must be analyzed and corrected before being reset.

The simple design of the refrigeration circuit totally eliminates potential problems during normal unit

operation. No maintenance work is needed on the refrigeration circuit as long as the unit is operating

normally.

Ease of maintenance has been taken into consideration during the design stage such that the unit is

easily accessible for servicing and maintenance. By accessing from the front panel of the unit,

servicing and maintenance operation can be done easily. The electrical components are especially easy

to access since it is located in the terminal box on top of the front panel.

Under normal circumstances, these chiller require only a check and cleaning of air intake through the coil

surface only. These can be done monthly or quarterly depending on the surrounding where the units are

installed.

When the surrounding is very oily or dusty, then the coils must be regularly cleaned by a qualified air

conditioner service technician to ensure sufficient cooling capacity and efficient unit operation. The

normal life span might be shortened if no proper service is provided.

Maintenance

For consistent performance and durability, always conduct proper and regular maintenance to the unit.

For prolong period of operation time, the heat exchanger will become dirty impairing its effectiveness and

reducing the performance of the units. Consult your local dealer about the cleaning of the heat

exchanger.

No major maintenance or servicing needed for the internal water circuit in the unit except the water pump

failure. It is advised that regular check on the filter to be conducted and change the water filter if the filter

is dirty or choked.

Always check the water level in the system, in order to protect the moving components in the hydraulic kit

from over heating and excessive wear.

62

Summary of Contents for M4AC 080 C

Page 10: ...5 2 Menu Structure Menu Structure Diagram for Chiller 9...

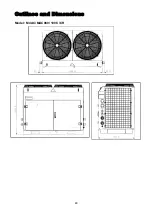

Page 49: ...Outlines and Dimensions Model M4AC MAC080 100 C CR 48...

Page 50: ...Model M4AC MAC120 150 C CR 49...

Page 52: ...Wiring Diagrams Model M4AC MAC080 100 120 150C Isolator Switch 51...

Page 53: ...Model M4AC MAC080 100 120 150C Terminal Block 52...

Page 54: ...Model M4AC MAC080 100 120 150CR Isolator Switch 53...

Page 55: ...Model M4AC MAC080 100 120 150CR Terminal Block 54...

Page 68: ...2004 McQuay International 1 800 432 1342 www mcquay com ISO 9002 REGISTERED...