Special Precautions for R407C

1) What is new refrigerant R407C?

R407C is a zeotropic refrigerant mixture which has zero ozone depletion potential and thus conformed

to the Montreal Protocol regulation. It requires Polyol ester oil (POE) oil for its compressor's lubricant.

Its refrigerant capacity and performance are about the same as the refrigerant R22.

2) Components

Mixture weight composition R32(23%), R125(25%), R134a(52%)

3) Characteristic

x

R407C liquid and vapor components have different compositions when the fluid evaporates or

condenses. Hence, when leak occurs and only vapor leaks out, the composition of the refrigerant

mixture left in the system will change and subsequently affect the system performance. If just additional

refrigerant is added to leaked system, system performance will drop. It is recommended that the system

should be evacuated thoroughly before recharging with R407C.

x

When refrigerant R407C is used, the composition will differ depending on whether it is in gaseous or

liquid phase. Hence when charging R407C, ensure that only liquid is being withdrawn from the cylinder

or can. This is to make certain that only original composition of R407C is being charged into the

system.

x

POE oil is used as lubricant for R407C compressor, which is different from the mineral oil used for R22

compressor. Extra precaution must be taken not to expose the R407C system too long to moist air.

4) Check list before installation/servicing

x

Tubing

Refrigerant R407C is more easily affected by dust of moisture compared with R22, make sure to

temporarily cover the ends of the tubing prior to installation

x

Compressor oil

No additional charge of compressor oil is permitted.

x

Refrigerant

No other refrigerant other that R407C

x

Tools

Tools specifically for R407C only (must not be used for R22 or other refrigerant)

i)

Manifold gauge and charging hose

ii)

Gas leak detector

iii)

Refrigerant cylinder/charging cylinder

iv)

Vacuum pump c/w adapter

v)

Flare tools

vi)

Refrigerant recovery machine

5) Handling and installation guidelines

Like R22 system, the handling and installation of R407C system are closely similar. All precautionary

measures; such as ensuring no moisture, no dirt or chips in the system, clean brazing using nitrogen, and

thorough leak check and vacuuming are equally important requirements. However, due to zeotropic nature

of R407C and its hydroscopic POE oil, additional precautions must be taken to ensure optimum and

trouble-free system operation.

a) Filter-dryer must be installed along the liquid line for all R407C air conditioners. This is to minimise the

contamination of moisture and dirt in the refrigerant system. Filter-dryer must be of molecular sieve

type. For a heat-pump system, install a two-way flow filter dryer along the liquid line.

b) During installation or servicing, avoid prolong exposure of the internal part of the refrigerant system to

moist air. Residual POE oil in the piping and components can absorb moisture from the air.

55

Summary of Contents for M4AC 080 C

Page 10: ...5 2 Menu Structure Menu Structure Diagram for Chiller 9...

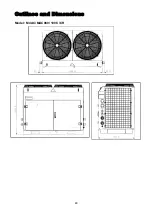

Page 49: ...Outlines and Dimensions Model M4AC MAC080 100 C CR 48...

Page 50: ...Model M4AC MAC120 150 C CR 49...

Page 52: ...Wiring Diagrams Model M4AC MAC080 100 120 150C Isolator Switch 51...

Page 53: ...Model M4AC MAC080 100 120 150C Terminal Block 52...

Page 54: ...Model M4AC MAC080 100 120 150CR Isolator Switch 53...

Page 55: ...Model M4AC MAC080 100 120 150CR Terminal Block 54...

Page 68: ...2004 McQuay International 1 800 432 1342 www mcquay com ISO 9002 REGISTERED...