6

7

GB

GB

carried out by an authorised customer services agent for Maxpro power tools.

ENVIRONMENT

Do not dispose of electric tools, accessories and packaging together with household waste material

- in observance of European Directive 2002/96/EC on waste of electric and electronic equipment and its

implementation in accordance with national law, electric tools that have reached the end of their life must

be collected separately and returned to an environmentally compatible recycling facility.

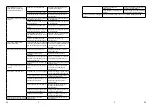

TROUBLE SHOOTING

Fault Symptom

Possible Cause

Troubleshooting

Out of service

Disconnection between plug and

power socket

Put plug in power socket

shortcircuit in power supply

Repair and reconnection

At switch-off

Switch on

Loose switching contact

Replace switchboard by repairer

Burnout of stator or rotor coil

Replace stator or rotor by repairer

Wearout of carbon brush

Replace carbon brush by repairer

Stator wiring disconnection

Reconnection by repairer

Disconnection between carbon

brush and commutator

Replace carbon brush

Sluggish start-up, falling short of

running speed

Unsmooth running in mechanical

part

Check mechanical part by repairer

Low supply voltage

Regulate supply voltage

Burnout of switch contact

Replace switchboard by repairer

Excessive sparkling during running Underpressure in carbon brush

spring

Replace carbon brush by reparier

Excessive wearout of carbon brush Replace carbon brush by reparier

Overvoltage in supply power

Regulate supply voltage

Disconnection between carbon

brush and commutator

Replace carbon brush

Ring fire caused by shortcircuit in

rotor winding shortcircuit

Check or replace rotor by repairer

Ring fire caused by shortcircuit in

commutator segment

Check or replace rotor by repairer

Failed to reach rated power

Electrocircuit overload due to

lighting device, public utility or

other electric appliances

No use of public utility or other

electric appliances on machine-

connected electrocircuit

Machine superheating

Electromotor overload

Overload protection

Excessive blunt drilling bit

Replace drilling bit

Insufficient lubricating oil or greasy

lubricating oil in reduction gearbox

Replenish or replace lubricating oil

by repairer

Insufficient motor cooling

Dedust air outlet

Gear shifting failure

Shifting fork or bearing damaged

Check and replace shifting fork or

bearing by repairer

Failure of mechanical shock

motion

Air cylinder or teleflex damaged

Check and replace air cylinder or

teleflex by repairer

Wearout of O-shape coil

Replace O-shape coil by repairer

Piston fracture or insufficient

lubricating oil

Replace piston or replenish

lubricating oil by repairer

Chock liner gets stuck

Repair chock liner by repairer

Disconnected running of spline

shaft or swinging bearing by

repairer

Replace spine shaft or swinging

bearing by repairer

Piston connecting rod fracture

Replace piston connecting rod by

repairer

No motion of drilling bit

during motor running

Rotor tooth fracture

Replace rotor by repairer

Gear wheel fracture

Replace gear wheel by repairer

Clutch gear slippage

Replace clutch gear by repairer

Spare parts list and drawing

Please download files on

www.maxpro-tools.com

Summary of Contents for 111-0900

Page 3: ......

Page 26: ...46 47 RU RU o o www maxpro tools com...

Page 31: ...56 57 FA FA 7 6 7 Vario lock SE SER 96 EC 2002 Maxpro O O 7...

Page 32: ...58 59 FA FA 16 13 Maxpro orpxaM 16 230 240 220 8 10 8 2 1 R 2 L 2 3 6 1 1...

Page 34: ...62 63 AR AR O O oiraV RES ES 2002 EC 96 7...

Page 35: ...64 65 AR AR 230 240 220 8 10 8 8 2 1 R 2 L 7 6 7 16 13 Maxpro Maxpro 16 1 1 2 6 6 3...

Page 37: ...www maxpro tools com...