Operation

29

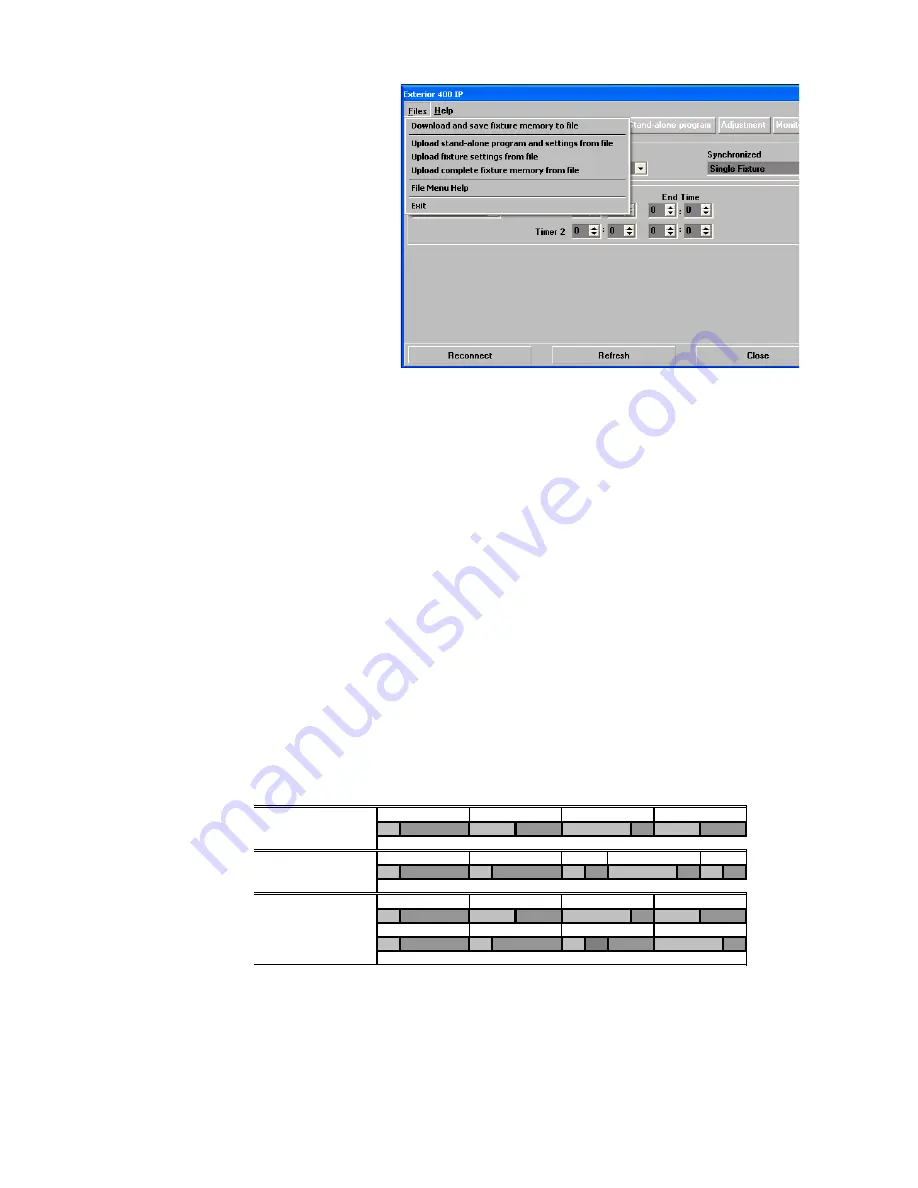

If you are programming a group

of fixtures to perform the same

scenes with synchronized

master/slave triggering, we

recommend that you:

1. Use MUM to program a show

on one slave fixture

2. Download and save this

fixture’s memory (program

and settings) to your PC

using MUM’s Files menu (see

Figure 17), and then

3. Upload the program and

settings to each subsequent

fixture that you connect to.

For a more detailed explanation

of synchronized operation and

how advanced effects can be

created by programming fixtures

with a different number of

scenes, see the next section.

Synchronized stand-alone operation: detailed description

Note:

This section gives advanced information about stand-alone synchronized operation. You only need

to read it if you require help with problem diagnosis or if you want to program advanced

synchronized light shows.

The principles in stand-alone synchronized operation are as follows:

1. A scene contains a fade section, followed by a wait section

2. Each fixture can be individually programmed with up to 100 scenes, and each scene can have its own

individual fade and wait times.

3. Scenes are numbered from 0 to 99.

4. In synchronized operation, one master fixture issues commands to the other slave fixtures to “go to

scene

xx

”, where

xx

is the scene number that the master will execute next.

5. If a slave has fewer scenes than the master, it will derive which scene to go to by dividing the number of

the scene it has been commanded to go to (scene 5, for example) by the total number of scenes that the

slave fixture has (4, for example) in whole numbers (no decimal places). In this example 5 divided by 4

results in 1, with 1 remainder. This remainder will be the number of the scene that the slave fixture starts

- scene 1. Generally though, when a Slave fixture reaches its own last scene before the Master fixture, a

“go to scene x

x

” message will result in the first scene being played.

6. If a slave has more scenes than the master calls, the last scenes in the slave will never be executed, as

is the case with scene S4 in the following example.

7. In synchronized operation, the wait time is determined by the master. Every slave fixture fades and

waits at its own rate and then remains in the “wait” state until it receives a “start scene xx” command

from the master.

8. A slave fixture will not listen for the next message from the master fixture before it has finished its

current scene. This may result in a slave skipping a scene if the slave has a longer scene time than the

master. Note that in the following example, the scenes in the slave run out of their programmed

Figure 17: Managing fixture settings and stand-alone programs

as files

F=fade, W=wait

Timeline =>

M0

M1

M2

M3

Programmed in Master

F

W

F

W

F

W

F

W

S0

S1

S2

S3

S4

Programmed in Slave

F

W

F

W

F

W

F

W

F

W

Result

M0

M1

M2

M3

F

W

F

W

F

W

F

W

S0

S1

S2

S3

F

W

F

W

F

W

--

-- F

W

Summary of Contents for Exterior 400

Page 1: ...user manual Exterior 400 Image Projector...

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ...www martin com Olof Palmes All 18 8200 Aarhus N Denmark Tel 45 8740 0000 Fax 45 8740 0010...