1

2

3

4

Removing and installing valves

91

Removing valves

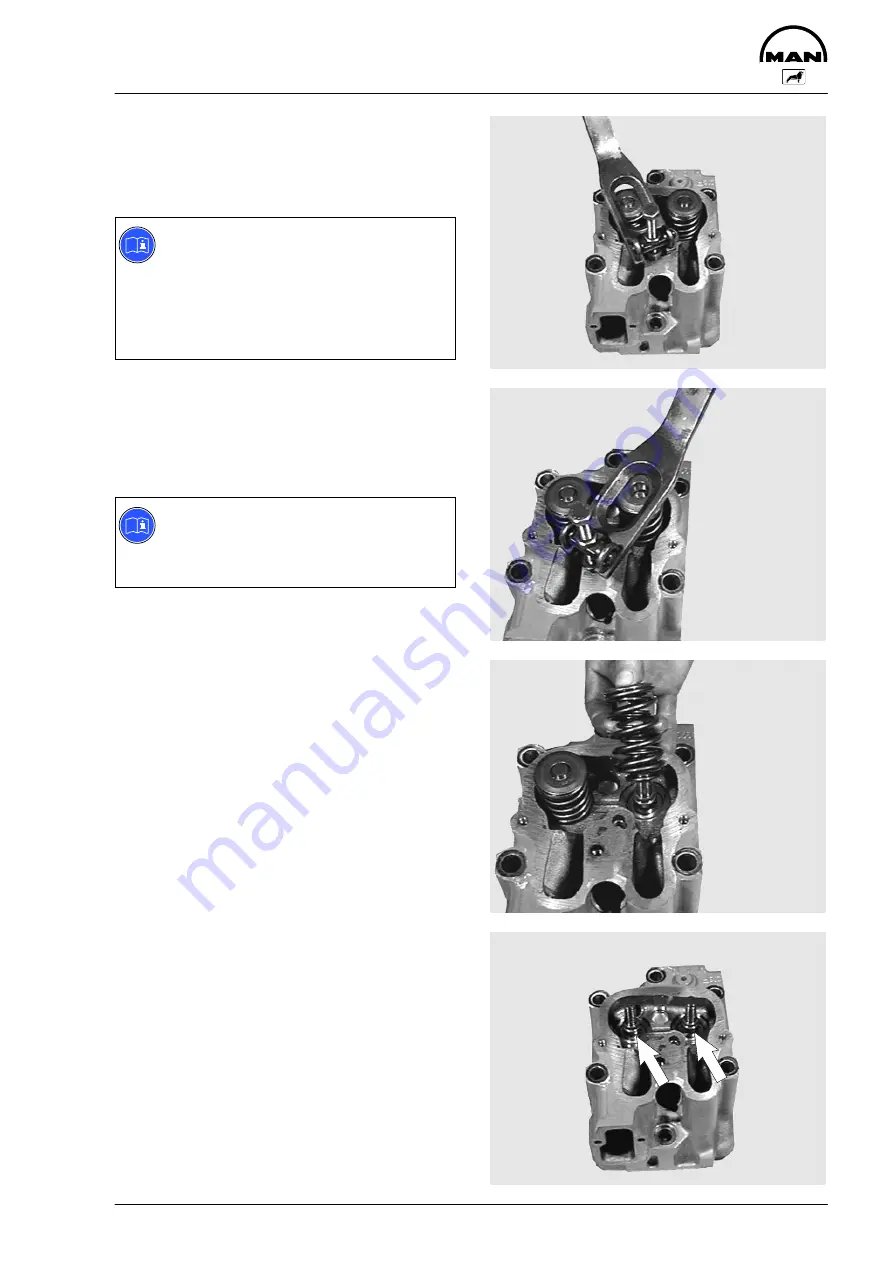

Remove rocker arms. Take off cylinder head,

see page 85.

Fig. 1

Note:

Valve spring and valve spring retainer

can also be replaced with the cylinder

head installed.

For this purpose the relevant piston must

be at TDC, and the valve assembly lever

is required.

D

Fit valve assembly lever to cylinder head

D

Screw in setting screw so that the lever points

slightly upwards

Fig. 2

Note:

If a valve fixture is available in the work-

shop, the procedure described may also

be carried out on the said fixture.

D

Press spring plate and spring downwards with

valve assembly lever and take out the valve

cone pieces using a magnet

D

Move assembly lever upwards -

Caution:

spring under tension, risk of injury

- and

away to one side

Figs. 3 and 4

D

Take off the upper spring plate, the valve

springs and the washer

D

Turn cylinder head over. Pull out inlet and ex-

haust valves and put them aside, arranging or

marking them in the sequence of installation

D

Turn cylinder head over again and pull off valve

stem seal (arrow)

D

Check the valves for damage, if necessary ex-

changing them

D

Measure the valve springs and exchange fati-

gued springs

D

Check the valve stems and guides for scores

and wear, if necessary measuring the guides

with a plug gauge

D

Check the valve seats for heavy indentation or

signs of burn-out, if necessary grinding the

valves or exchanging the seat insert

D

Rework valve seat insert (see instructions of

milling machine manufacturers), or if necessary

exchange it

Summary of Contents for D 2866 LUE 605

Page 1: ......

Page 2: ......

Page 14: ...Notes 12...

Page 19: ...Memoranda 17...

Page 20: ...Engine views 18 Engine views 3 4 2 1 7 6 5 8 11 10 9...

Page 68: ...Memoranda 66...

Page 133: ...131 Service Data...

Page 157: ...155 Special tools...

Page 158: ...Special tools 156 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Page 162: ...Special tools 160 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 23 28...

Page 164: ...Special tools 162 30 31 32 1 32 32 2...

Page 167: ...Special tools 165 Pressing mandel for cap dia 62 1 mm Pressing mandel for cap dia 50 1 mm...

Page 170: ...Notes 168...

Page 173: ......

Page 174: ......