5

6

7

8

Removing and installing cylinder head

86

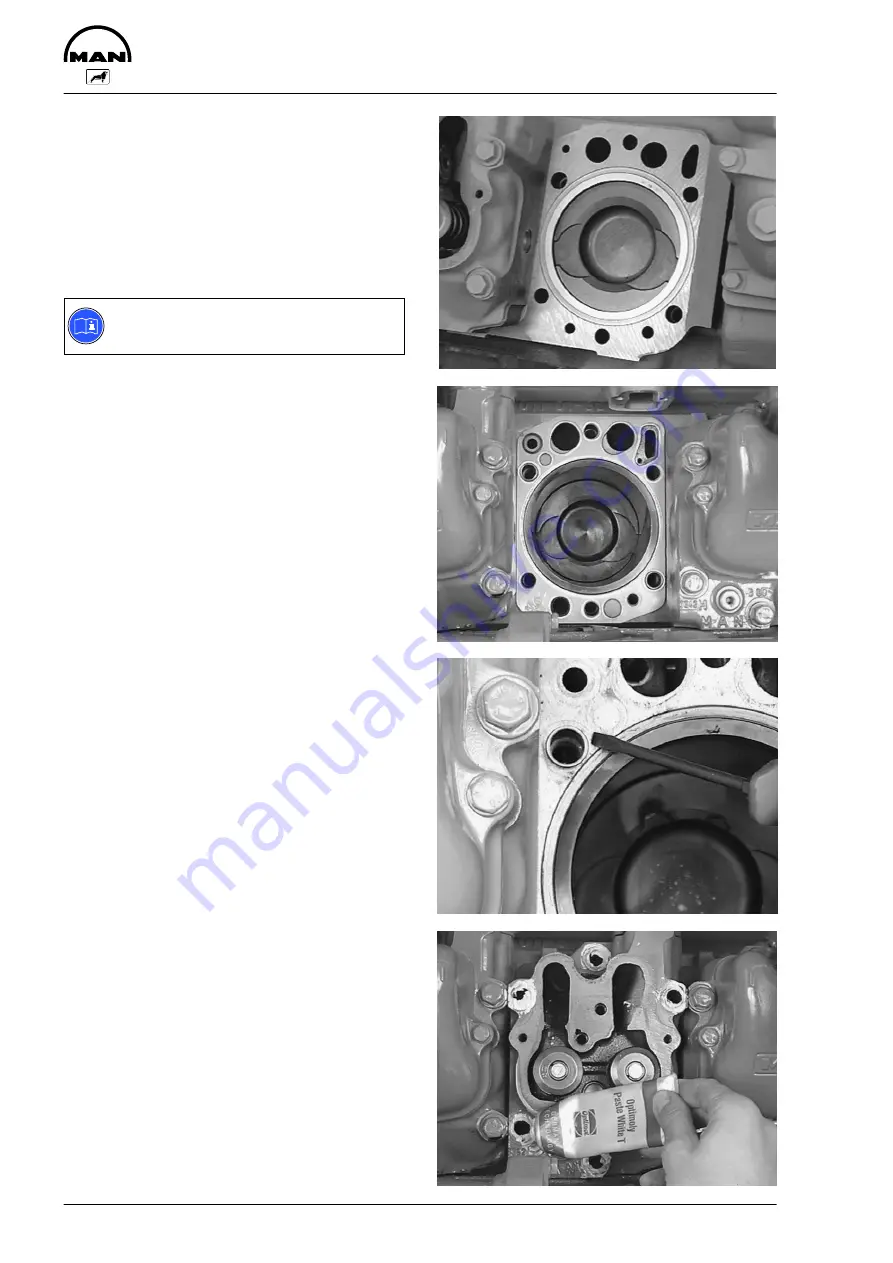

Fig. 5

Take off cylinder head and cylinder head gasket.

Check whether cylinder head sealing face and cyl-

inder block are plane using a straight edge.

Non-plane cylinder heads can be remilled 1 mm.

Notice specified projection of injection nozzles and

valve recess.

Note:

Check cylinder heads for cracks.

Installing cylinder head

Fig. 6

Before installation clean and blow out threaded

bores in crankcase. Clean sealing faces on cylin-

der head and crankcase.

Lay new cylinder head gaskets in place in dry

condition, ensuring that the holes match those in

the crankcase, and place cylinder head on top.

Fig. 7

Each cylinder head is located with two fitting

sleeves.

Fig. 8

Check whether the cylinder head bolts have the

max. permissible length.

Bolts that have been removed may be used again

if the max. permissible length is not exceeded.

Coat cylinder head bolts with engine oil before in-

serting them and apply “Optimoly WhiteT” assem-

bly paste to the contact face of the bolt head.

Summary of Contents for D 2866 LUE 605

Page 1: ......

Page 2: ......

Page 14: ...Notes 12...

Page 19: ...Memoranda 17...

Page 20: ...Engine views 18 Engine views 3 4 2 1 7 6 5 8 11 10 9...

Page 68: ...Memoranda 66...

Page 133: ...131 Service Data...

Page 157: ...155 Special tools...

Page 158: ...Special tools 156 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Page 162: ...Special tools 160 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 23 28...

Page 164: ...Special tools 162 30 31 32 1 32 32 2...

Page 167: ...Special tools 165 Pressing mandel for cap dia 62 1 mm Pressing mandel for cap dia 50 1 mm...

Page 170: ...Notes 168...

Page 173: ......

Page 174: ......