5

6

7

Repairing coolant pump with high-temperature and

low-temperature parts D 2866 LUE 605

49

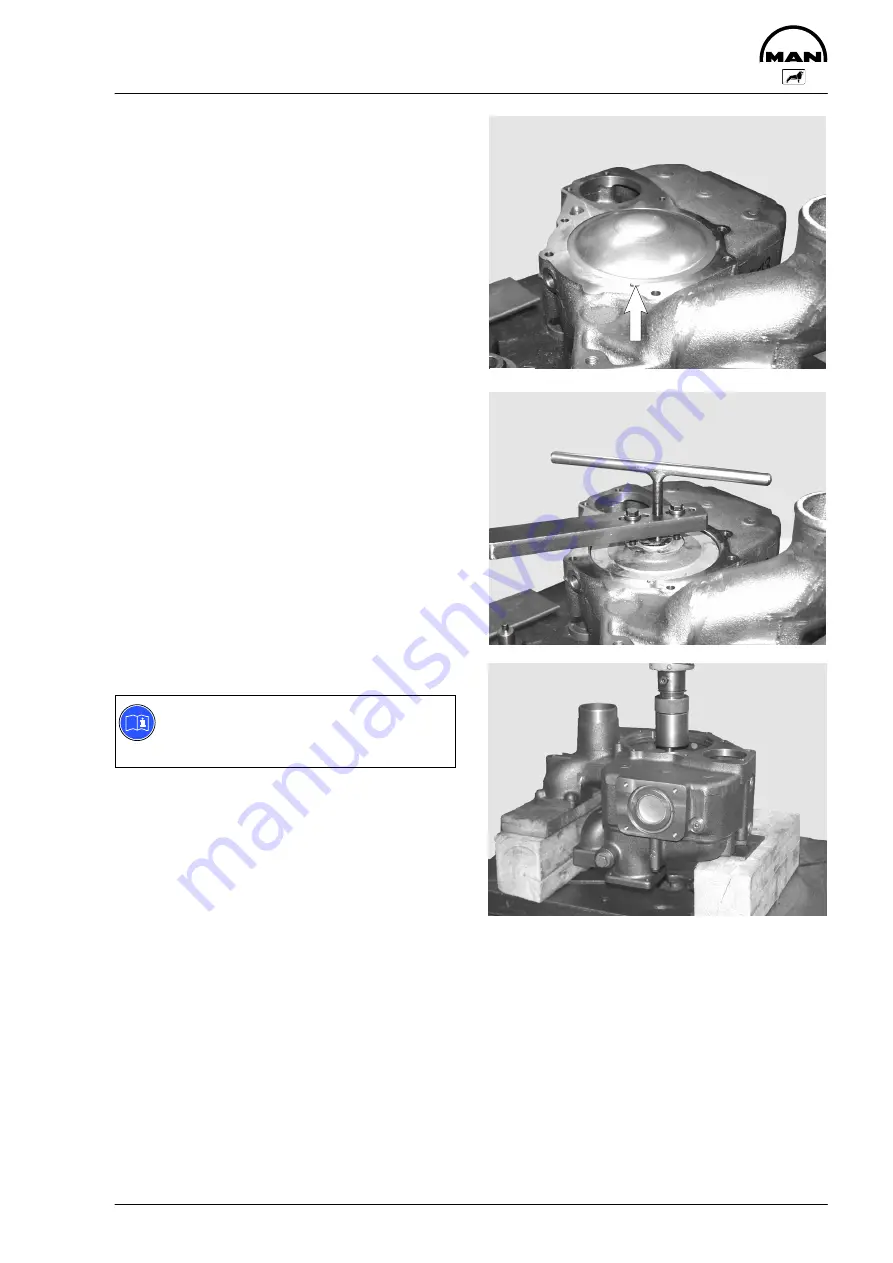

Fig. 5

Knock out cover by driving a suitable mandrel un-

der it (Fig. 1, item 3) at notch (arrow).

Fig. 6

Pull impeller off coolant pump shaft.

For this purpose four threaded bores M8 are provi-

ded.

Fig. 7

Note:

Remove bolt from low-temperature part

(Fig. 1, item 5).

Align water pump housing on a suitable and stable

surface.

Use a suitable mandrel to press the water pump

shaft together with bearing out of the housing.

Take off mechanical seal.

The high-temperature part and the low-tempera-

ture suction part are now separated.

Remove axial face seals and grooved ball bearing

from high-temperature part if they are still in the

housing.

Summary of Contents for D 2866 LUE 605

Page 1: ......

Page 2: ......

Page 14: ...Notes 12...

Page 19: ...Memoranda 17...

Page 20: ...Engine views 18 Engine views 3 4 2 1 7 6 5 8 11 10 9...

Page 68: ...Memoranda 66...

Page 133: ...131 Service Data...

Page 157: ...155 Special tools...

Page 158: ...Special tools 156 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Page 162: ...Special tools 160 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 23 28...

Page 164: ...Special tools 162 30 31 32 1 32 32 2...

Page 167: ...Special tools 165 Pressing mandel for cap dia 62 1 mm Pressing mandel for cap dia 50 1 mm...

Page 170: ...Notes 168...

Page 173: ......

Page 174: ......