9

10

11

Removing and installing valves

93

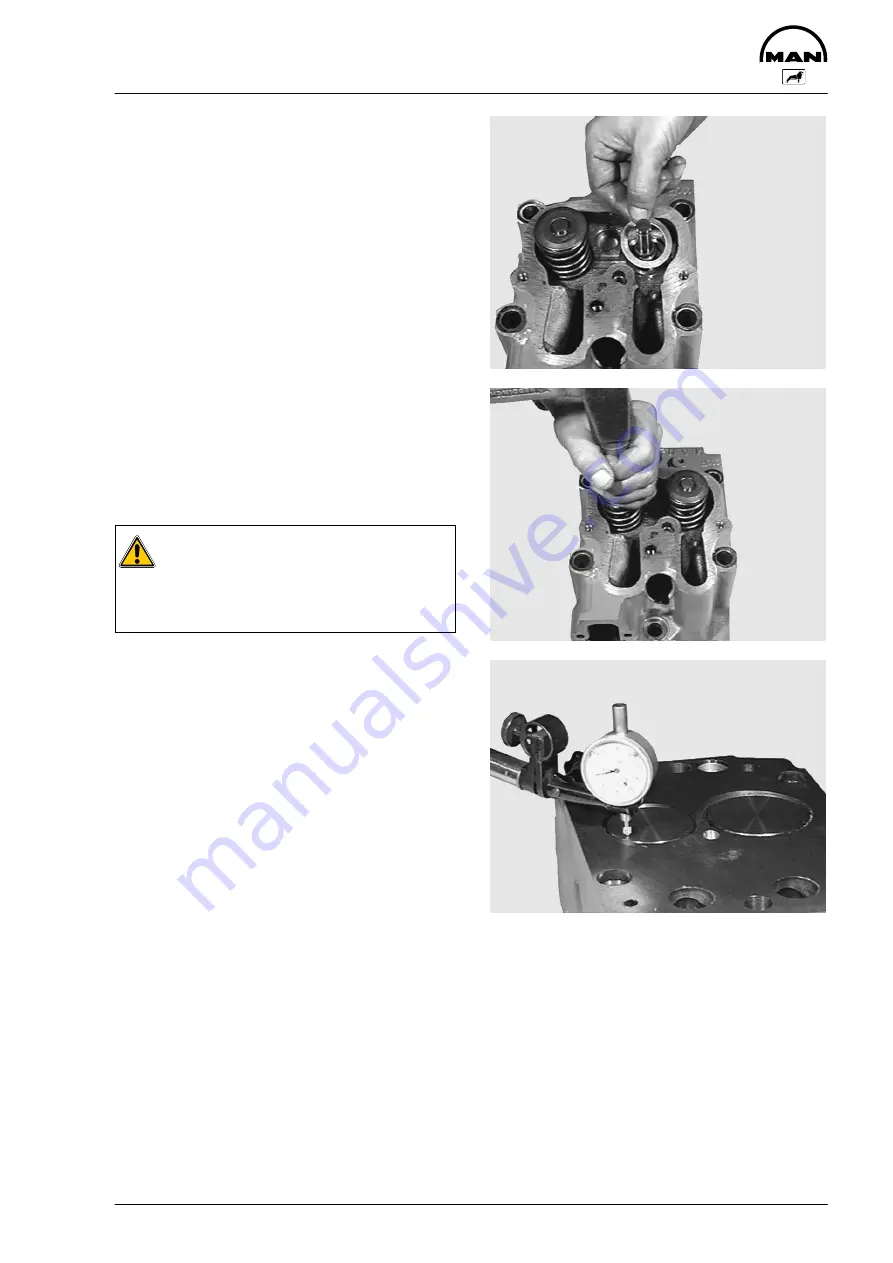

Fig. 9

Screw valve assembly lever on to cylinder head.

Insert the valve spring washers.

Insert discs and valve springs.

The word “TOP” facing upwards, the tight coils

facing downwards.

Replace damaged or weak springs.

Fig. 10

Compress the valve springs using assembly lever

and insert the valve cone pieces.

Use suitable tool to lightly knock back the valve

springs to ensure that the valve cone pieces sit

correctly.

Caution:

Ensure that the valve cone pieces sit cor-

rectly, since valve cone pieces which

jump out may cause considerable da-

mage.

Measuring valve recess

Fig. 11

D

Place dial gauge holder and dial gauge on cylin-

der head

D

Apply gauge tip under preload to cylinder head

D

Set dial gauge to “0”

D

Slew dial gauge towards the valve disc and

read off retrusion, if necessary exchanging

valve and valve seat insert

Summary of Contents for D 2866 LUE 605

Page 1: ......

Page 2: ......

Page 14: ...Notes 12...

Page 19: ...Memoranda 17...

Page 20: ...Engine views 18 Engine views 3 4 2 1 7 6 5 8 11 10 9...

Page 68: ...Memoranda 66...

Page 133: ...131 Service Data...

Page 157: ...155 Special tools...

Page 158: ...Special tools 156 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Page 162: ...Special tools 160 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 23 28...

Page 164: ...Special tools 162 30 31 32 1 32 32 2...

Page 167: ...Special tools 165 Pressing mandel for cap dia 62 1 mm Pressing mandel for cap dia 50 1 mm...

Page 170: ...Notes 168...

Page 173: ......

Page 174: ......