5

6

7

Removing and installing flywheel, replacing starter gear ring

73

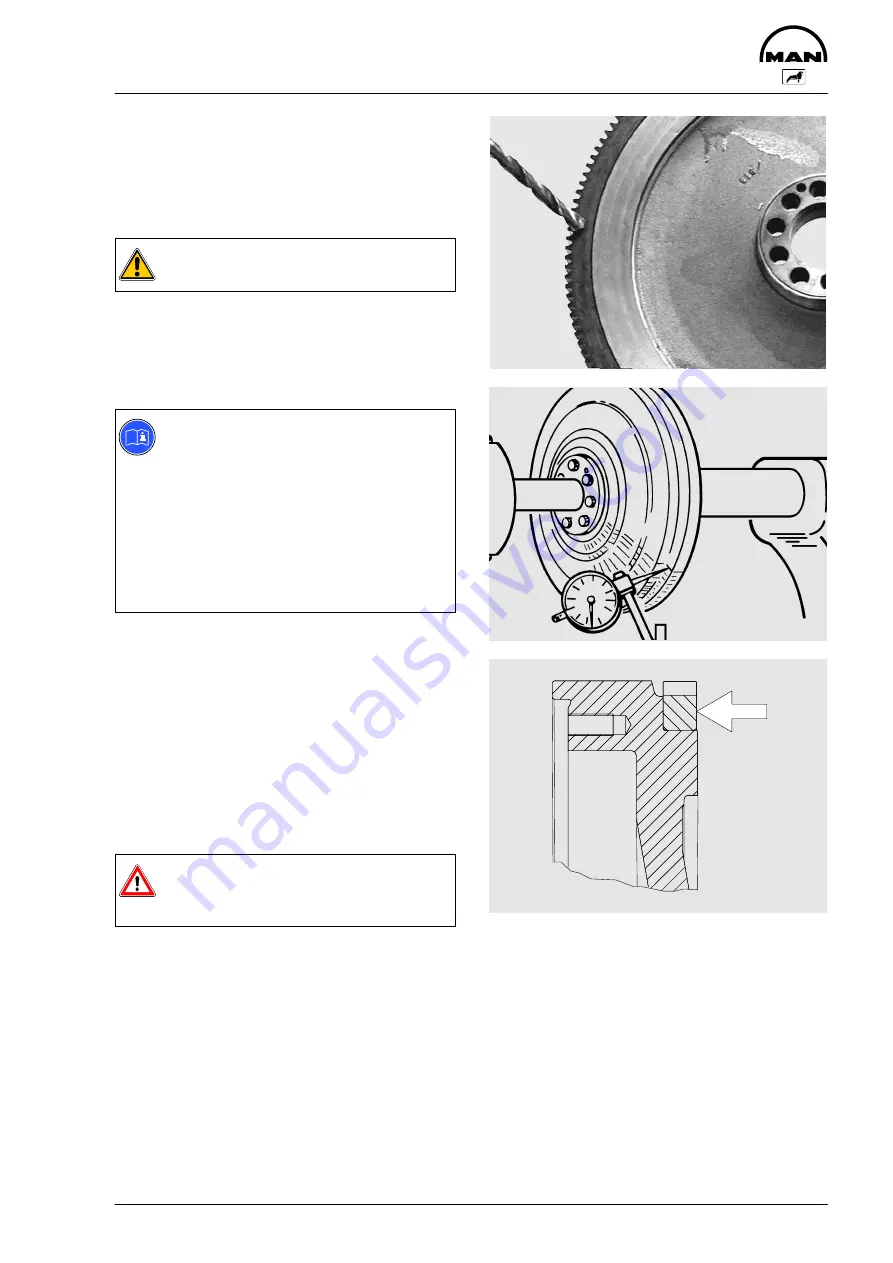

Replacing starter gear ring

Fig. 5

Remove the flywheel.

Drill the starter motor toothed wheel and break

with a chisel.

Caution:

In doing so, do not damage the flywheel.

Fig. 6

Note:

As the maximum axial run-out of the

starter motor toothed wheel must not be

exceeded, the axial run-out of the flyw-

heel should be measured on the contact

surface of the starter motor toothed

wheel prior to shrinking on the starter mo-

tor toothed wheel.

If the required value is exceeded, replace

the flywheel.

Engage the flywheel at the hub.

Apply the dial gauge to the contact surface of the

toothed wheel.

Rotate the flywheel by hand through several re-

volutions and observe the needle deflection on the

dial gauge.

Fig. 7

Heat the new starter ring gear to approx. 200

°

C to

230

°

C and press on as far as it will go.

Danger:

The parts are hot! Risk of burns!

Wear protective gloves.

Check the axial runout and compare with the max.

permissible value.

Summary of Contents for D 2866 LUE 605

Page 1: ......

Page 2: ......

Page 14: ...Notes 12...

Page 19: ...Memoranda 17...

Page 20: ...Engine views 18 Engine views 3 4 2 1 7 6 5 8 11 10 9...

Page 68: ...Memoranda 66...

Page 133: ...131 Service Data...

Page 157: ...155 Special tools...

Page 158: ...Special tools 156 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Page 162: ...Special tools 160 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 23 28...

Page 164: ...Special tools 162 30 31 32 1 32 32 2...

Page 167: ...Special tools 165 Pressing mandel for cap dia 62 1 mm Pressing mandel for cap dia 50 1 mm...

Page 170: ...Notes 168...

Page 173: ......

Page 174: ......