43

Magtrol Model DSP6001 Dynamometer Controller

Chapter 5 – PID Settings

SETUP

5.4.1.3

Setting Additional Scale Factor for D (Derivative)

1. Starting from the main menu, press and hold the D button. While holding the D button,

press SHIFT.

2. Use the D button to toggle through the letters in the unit (A, B, C, D, E, F, G, H and I).

3. Choose the letter that corresponds with the pre-determined setting provided in the Additional

Scale Factor Table shown in

Appendix F

.

4. Once the letter is chosen, press SHIFT to return to the main menu.

5.5

SETTING THE CORRECT PID’S FOR YOUR MOTOR

Note:

Each type of motor will have it’s own optimum PID setting at

different load points.

5.5.1

S

etting

tHe

piD

witH

an

U

nknown

M

otor

or

S

ySteM

If the user is unfamiliar with the characteristics of the motor under test, it is recommended to

begin in Open Loop Control mode. In doing so, the user can safely get an idea of the motor’s

performance.

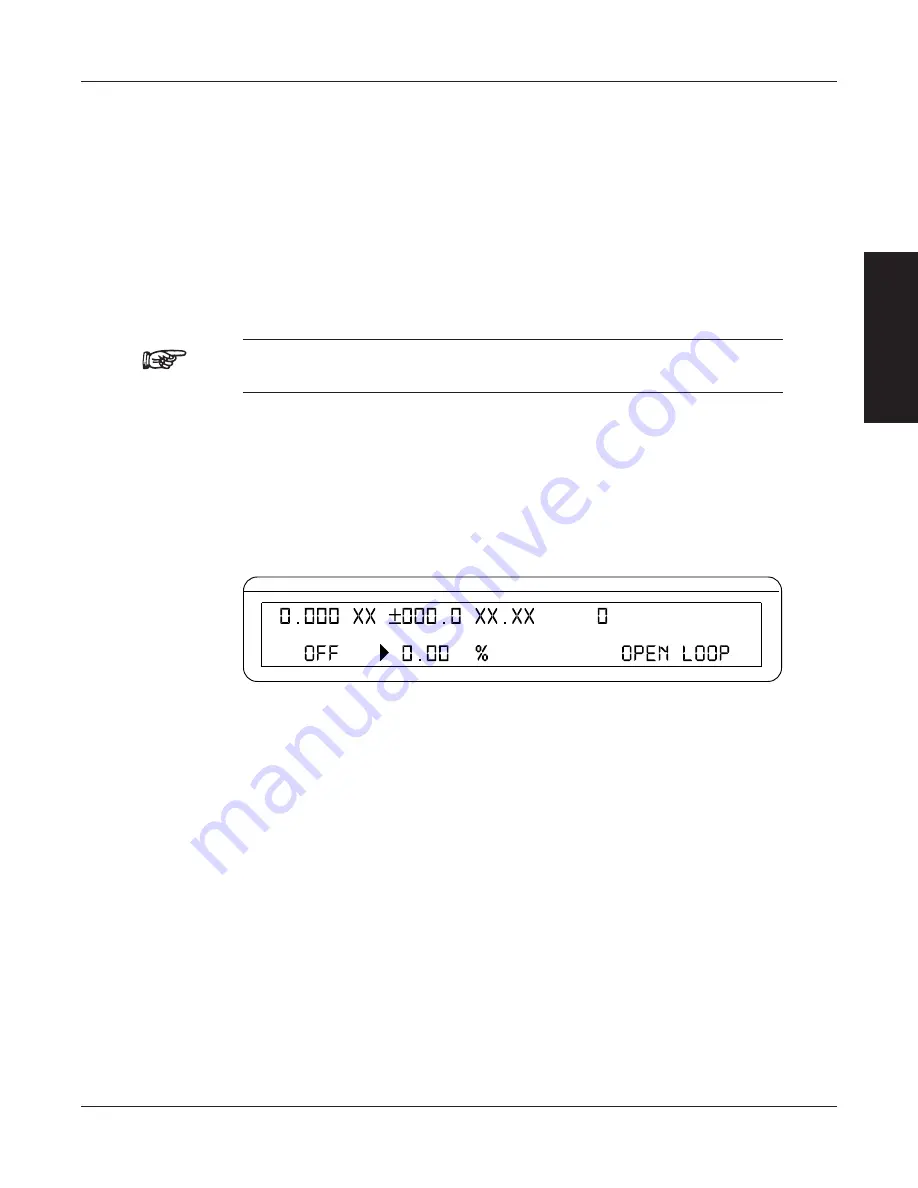

1. To enter Open Loop Control mode, begin with the motor and brake OFF. Press and hold the

TORQUE SET button until a second beep is heard. The display will appear as follows:

POWER

BRAKE STATUS

SET POINT

SET POINT

P

I

D

TORQUE

SPEED

STATUS

Figure 5–2 Open Loop Control Menu

2. Set the percent excitation to zero.

3. Start the motor.

4. Slowly increase the excitation current to the brake.

5. Make a note of the torque and speed values of which the motor is capable.

6. To exit the Open Loop Control mode and return to the main menu, turn the motor and brake

OFF and press and hold the TORQUE SET button until a second beep is heard.

5.5.2

S

etting

tHe

piD

for

t

orqUe

C

ontroL

1. With the motor and brake OFF, set the desired Torque Set Point by pressing the TORQUE

SET button and using the UP

and DOWN

buttons and Decrease/Increase dial.

2. Set the P, I and D values to zero.

3. Turn the motor ON.

4. Turn the brake ON.

5. Slowly increase the P term until the torque read is about 25% of the desired load point.