6. Installation

6.1. Installation procedure

Before unpacking the laser, prepare for the installation by making sure that the required equipment,

resources and materials are available. Carefully inspect the package contents for shipment damage and

notify Luxinar immediately if any damage is found.

• The means to transport and lift the laser into position. See section

for equipment weights.

• A flat surface with prepared fixing locations to match the laser mounting feet. See section

.

• A DC power supply supplied by Luxinar or sourced locally.

• A beam delivery system and supports with a prepared connection for the laser output window

mounting point.

• A source of cooling water or a chiller for laser cooling. See section

.

• A source of high purity nitrogen or compressed air to provide a positive purge pressure for the laser

optics. See section

• Emergency stop interlock circuit.

• Laser control interface circuitry.

Perform the following steps to install the laser:

1.

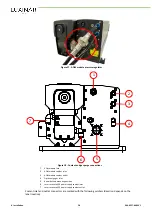

Carefully unpack the laser and place it on the prepared mounting surface, then fasten it in place

using M8 bolts. Do not remove the protection cap from the laser output window at this stage.

See section

2.

Connect the laser to the cooling water source or chiller using 10mm OD tubing (see section

).

To connect the cooling tubing:

a.

Push the tube into the connector until it reaches the stop. Pull back on the tube to ensure that

the connector has gripped the tube firmly.

b.

To remove the tube, press the release ring on the end of the connector end and pull out the

tube.

3.

Connect the optics purge gas supply using 6mm OD tubing (see section

. To connect the gas

purge tubing:

a.

Push the tube into the connector until it reaches the stop. Pull back on the tube to ensure that

the connector has gripped the tube firmly.

b.

To remove the tube, press the release ring on the end of the connector end and pull out the

tube.

4.

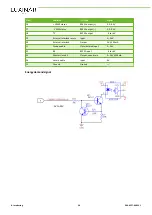

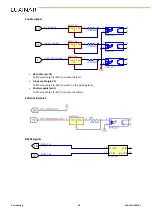

Connect the laser to the DC power supply.

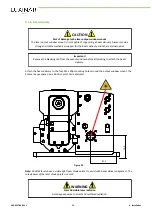

DANGER

Exposed terminals — risk of electrocution

Switch off and disconnect the equipment from the mains electrical supply before exposing

electrical terminals. Only trained and authorised personnel should make electrical

connections.

5.

Connect the DC power supply to the mains. See section

.

6.

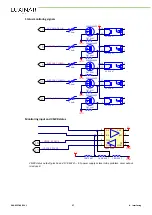

Connect the emergency stop interlock circuit.

7.

Connect the control interface circuitry.

8.

Test the laser output before fitting the beam delivery.

Place a suitable beam block or power monitoring device in the beam path. Do not place it close to

optical surfaces to avoid risk of contamination by evaporated material.

906-0227-00 REV 1

23

6. Installation

Summary of Contents for SR 10 AOM

Page 1: ...USER MANUAL SR AOM series Sealed CO2 laser sources with integrated AOM...

Page 8: ...Preface iv 906 0227 00 REV 1...

Page 40: ...6 Installation 32 906 0227 00 REV 1...

Page 42: ...7 Transport and recommissioning 34 906 0227 00 REV 1...

Page 52: ...8 Interfacing 44 906 0227 00 REV 1...