Maintenance

Maintenance on the ball valve

22

© Lutz-Jesco GmbH 2018

BA-24721-02-V02

Chlorine gas changeover unit

C 7523

Operating instructions

Perform the following working steps:

1.

Loosen the union nuts and remove the three connections. Remove

the O-rings with a blunt tool.

2.

Clean the sealing surfaces with a soft cloth.

3.

Check the display of the contact gauge At atmospheric pressure, it

must display approx. zero. Otherwise, it needs to be cleaned.

4.

Look into the interior of the ball valve. Should soiling be visible, the

ball valve requires cleaning from inside.

5.

Switch the motor to MAN and move the ball valve on the hand lever. It

must revolve evenly around 180° with slight resistance. Otherwise, it

will be necessary to perform maintenance on the ball valve. Switch

the motor to AUTO.

6.

Fit the new O-rings and the connections. The union nuts are tight-

ened by hand.

ü

Small maintenance performed.

11.5 Cleaning the contact gauge

NOTE

Damage to pressure gauges

Pressure gauges are measurement devices which are adjusted by spe-

cialists when manufactured. Pressure gauges that have been disas-

sembled must be tested and readjusted by the manufacturer.

ð

Do not dismantle pressure gauges.

ð

Pressure gauges are highly complicated which cannot be emptied

entirely.

ð

Do not allow any soiling to enter the pressure gauge.

ð

Do not allow any water to enter the pressure gauge.

The maintenance on the pressure gauge restricts itself to a visual check

and the cleaning of the connection.

Precondition for action:

ü

The system has been prepared for maintenance (see 12.3).

ü

The changeover unit is free of stress.

Resources required:

@

PTFE strip

@

Cotton swabs

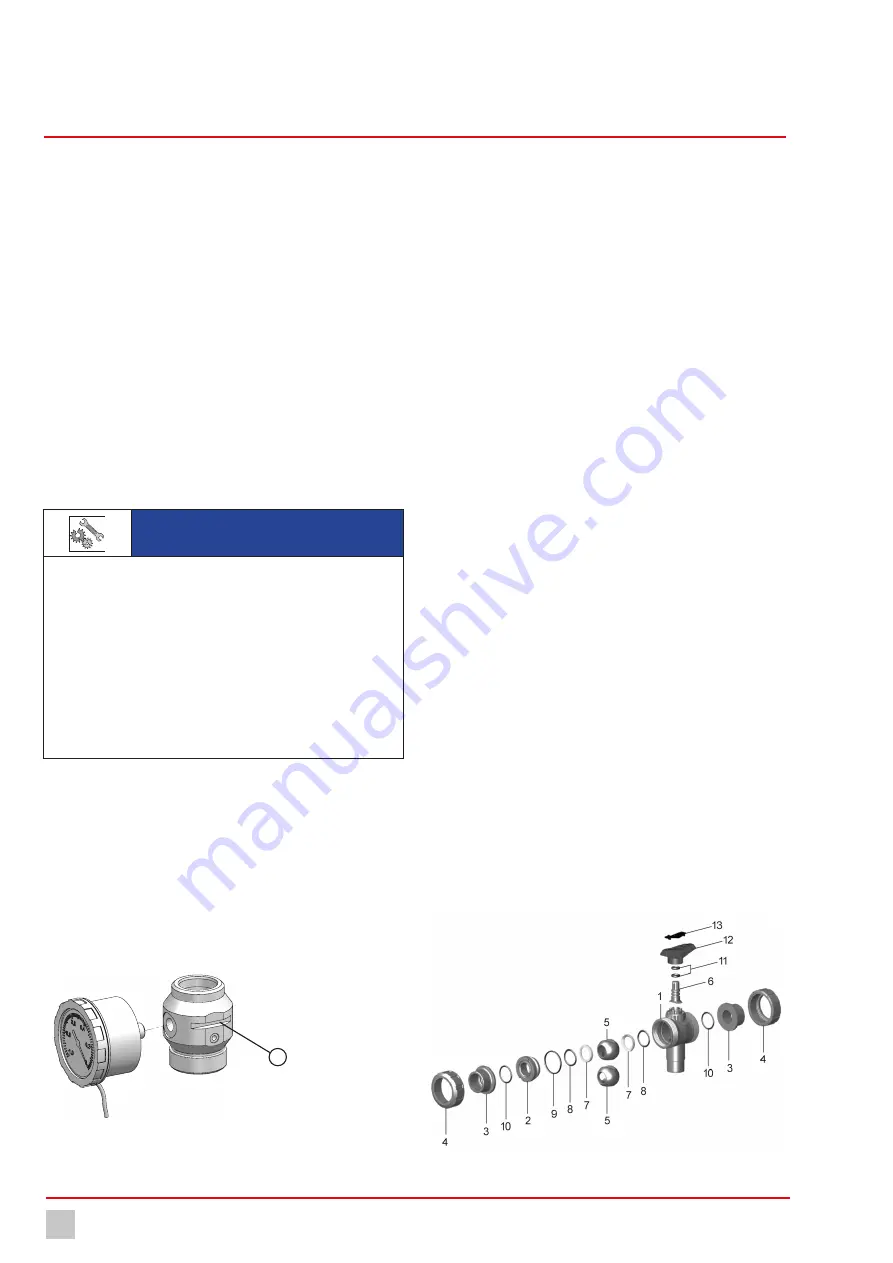

Fig. 19: Remove the pressure gauge

Perform the following working steps:

1.

Separate the pressure gauge cable from the control and pull it out of

the cable guide (1).

2.

Unscrew the pressure gauge from the pressure gauge connection.

Remove the PTFE strip from the thread.

3.

Check the input of the pressure gauge for contamination. Remove the

contamination with isopropyl alcohol. At the same time, hold the

pressure gauge with the connection facing downwards so that soil-

ing cannot fall into the device. Do not use a pointed tool, so that the

protective film on the plate spring is not destroyed.

4.

If the pressure gauge is not immediately reconnected, seal the con-

nection airtight.

5.

Fit the pressure gauge with approx. 5 long PTFE strips.

6.

Return the cable to the control and reconnect it.

ü

Contact gauge cleaned.

11.6 Maintenance on the ball valve

Precondition for action:

ü

The system has been prepared for maintenance.

ü

The changeover unit is free of stress.

Resources required:

@

Ball valve grip (part of the maintenance set)

@

Silicone grease

Perform the following working steps:

1.

Note the switching position of the ball valve.

2.

Remove the four screws below on the motor. Remove the motor from

the wall console.

3.

Remove the four screws above on the ball valve.

4.

Remove the two screws from the side on the pressure gauge con-

nection.

5.

Remove the ball valve and the pressure gauge connection from the

wall console.

6.

Disconnect the ball valve and the pressure gauge connection.

7.

Dismantle the ball valve. The screw-in fitting (2) has a left-hand

thread and the hand lever (12+13) is used as a tool.

Fig. 20: Individual parts of the ball valve

1