5

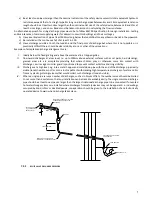

4.1.2

D

IMENSIONS

4.1.3

C

ONNECTION SIZES

Size

Description

Unit

LBT300

LBT500

LBT800

LBT1000

LBT1500

LBT2000

LBT2500

A

Connection ASHP return

mm

325

345

290

290

360

390

425

B

Height of Tank body connection

mm

695

715

660

780

810

930

865

C

Height of Tank body connection

mm

1065

1085

1030

1270

1260

1470

1305

D

Connection ASHP flow

mm

1435

1455

1400

1760

1710

2010

1745

E

Height of Immersion heater connection

mm

880

975

845

1020

1085

1200

1145

H

Total Height (with insulation)

mm

1680

1715

1740

2100

2140

2470

2220

H

Height of AAV Connection

mm

1680

1715

1740

2100

2140

2470

2220

De

Diameter of Water Heater (with insulation)

mm

610

710

990

990

1240

1340

1450

Size

Description

Unit

LBT3000

LBT4000

LBT5000

LBT6000

LBT8000

LBT10000

A

Connection ASHP return

mm

435

480

510

635

625

625

B

Height of Tank body connection

mm

1035

1080

1110

1155

1385

1635

C

Height of Tank body connection

mm

1635

1680

1710

1675

2145

2645

D

Connection ASHP flow

mm

2235

2280

2310

2195

2905

3655

E

Height of Immersion heater connection

mm

1435

1430

1510

1415

1615

2365

H

Total Height (with insulation)

mm

2720

2810

2870

2790

3490

4240

H

Height of AAV Connection

mm

2720

2810

2870

2790

3490

4240

De

Diameter of Water Heater (with insulation)

mm

1450

1600

1800

2000

2000

2000

Size

Description

Unit

LBT300

LBT500

LBT800

LBT1000

LBT1500

LBT2000

LBT2500

sa

Connection Air vent

BSP

1"

1"

1"

1"

1"

1"

1"

g

Connection Tank body

BSP

1¼"

1¼"

1¼"

1¼"

1¼"

1¼"

1¼"

mc

Connection ASHP flow

BSP

1¼"

1¼"

1½"

1½"

1½"

1½"

2"

rc

Connection ASHP return

BSP

1¼"

1¼"

1½"

1½"

1½"

1½"

2"

mi

Connection heating system flow

BSP

1¼"

1¼"

1½"

1½"

1½"

1½"

2"

ri

Connection heating system return

BSP

1¼"

1¼"

1½"

1½"

1½"

1½"

2"

rp

Connection alternate heating system return

BSP

1¼"

1¼"

1½"

1½"

1½"

1½"

2"

sc

Connection Drain

BSP

1¼"

1¼"

1½"

1½"

1½"

1½"

2"

sd

Connection sensor point

BSP

½"

½"

½"

½"

½"

½"

½"

z

Connection Immersion heater

BSP

1½"

1½"

1½"

1½"

1½"

1½"

1½"

Size

Description

Unit

LBT3000

LBT4000

LBT5000

LBT6000

LBT8000

LBT10000

sa

Connection Air vent

BSP

1"

1"

1"

1"

1"

1"

g

Connection Tank body

BSP

2"

2"

2"

2"

2"

2"

mc

Connection ASHP flow

BSP

2"

2"

2"

3"

3"

3"

rc

Connection ASHP return

BSP

2"

2"

2"

3"

3"

3"

mi

Connection heating system flow

BSP

2"

2"

2"

3"

3"

3"

ri

Connection heating system return

BSP

2"

2"

2"

3"

3"

3"

rp

Connection alternate heating system return

BSP

2"

2"

2"

3"

3"

3"

sc

Connection Drain

BSP

2"

2"

2"

3"

3"

3"

sd

Connection sensor point

BSP

½"

½"

½"

½"

½"

½"

z

Connection Immersion heater

BSP

1½"

1½"

1½"

1½"

1½"

1½"