6

5.0

GENERAL REQUIREMENTS

The Lochinvar LBT thermal store has been designed to operate trouble free for many years. These instructions should be

followed closely to obtain the maximum usage and efficiency of the equipment. PLEASE read the instructions fully before

installing or using the appliance. These instructions should be read in conjunction with the appropriate Heat pump

installation manual.

5.1

Related Documents

The installation should follow the relevant guidance offered in the following documents. It is not practical to list all relevant

information, but emphasis is placed on the following documents, as failure to comply with the guidance given will almost

certainly result in an unsatisfactory installation:

BS 6700: 1997

Design, installation, testing and maintenance of services supplying water for domestic use within

buildings and their curtilages

BS 7074: 1989

Application, selection and installation of expansion vessels and ancillary equipment for

Parts 1 and 2

sealed water systems. Code of practice for domestic heating and hot water supply

BS 7671: 2008

Requirements for electrical installations, I.E.E. wiring regulations seventeenth edition

CP 342:

Code of practice for centralised hot water supply-buildings other than dwellings

Part 2 1974

6.0

WATER QUALITY

6.1

Vessel

On systems where the LBT is working with Heat Pumps, CHP, Gas condensing boilers or any other direct heat source then

the LBT should be treated as per the rest of the system. See main heat source ICM for further guidance.

7.0

WATER CONNECTIONS

7.1

General

1.

Circulating pipework should be insulated; cisterns, expansion vessels and pipework situated in areas exposed to

freezing conditions should also be insulated.

2.

Drain valves must be located in accessible positions that will permit draining of the entire system.

3.

Individual valves should be fitted to each unit to enable isolation from the system.

7.2

Storage Vessel

The safety valve must be rated no higher than 5 bar. There must be no isolating valves between the LBT

and this safety valve.

The connections used will depend upon the system the LBT is fitted to; you must consult the relevant drawing and /or ICM

instructions for the Solar thermal or Heat pump also being installed.

7.2.1

RELIEF VALVE DISCHARGE PIPEWORK

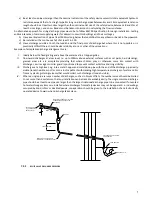

It is important that any discharge water does not collect in the discharge pipe-work and can run freely to the tundish. The

tundish should be mounted in a vertical and visible position located in the same space as the unvented hot water storage

system and be fitted as close as possible and within 600mm of the safety device e.g. the temperature relief valve.

The discharge pipe from the tundish should terminate in a safe place where there is no risk to persons in the vicinity of the

discharge, be of metal or other material that has been demonstrated to be capable of safely withstanding temperatures of

the water discharged and is clearly and permanently marked to identify the product and performance standard, and: