7

a)

Be at least one pipe size larger than the nominal outlet size of the safety device unless its total equivalent hydraulic

resistance exceeds that of a straight pipe 9m long i.e. discharge pipes between 9m and 18m equivalent resistance

length should be at least two sizes larger than the nominal outlet size of the safety device, between 18 and 27m at

least 3 sizes larger, and so on. Bends must be taken into account in calculating the flow resistance.

An alternative approach for sizing discharge pipes would be to follow BS6700 Specification for design installation, testing

and maintenance of services supplying water for domestic use within buildings and their curtilages.

b)

Have a vertical section of pipe at least 300mm long, below the tundish before any elbows or bends in the pipework.

c)

Be installed with a continuous fall of at least 1 in 200.

d)

Have discharges visible at both the tundish and the final point of discharge but where this is not possible or is

practically difficult there should be clear visibility at one or other of these locations.

Examples of acceptable discharge arrangements are:

I.

Ideally below the fixed grating and above the water seal in a trapped gulley.

II.

Downward discharges at a low level; i.e. up to 100mm above external surfaces such as car parks, hard standings,

grassed areas etc. are acceptable providing that where children play or otherwise come into contact with

discharges, a wire cage or similar guard is positioned to prevent contact whilst maintaining visibility.

III.

Discharges at a high level; e.g. into a metal hopper and metal down pipe with the end of the discharge pipe clearly

visible (tundish visible or not) or onto a roof capable of withstanding high temperature discharges of water and 3m

from any plastic guttering systems that would collect such discharges (tundish visible).

IV.

Where a single pipe serves a number of discharges, such as in blocks of flats, the number served should be limited

to not more than 6 systems so that any installation can be traced reasonably easily. The single common discharge

pipe should be at least one pipe size larger than the largest individual discharge pipe to be connected. If unvented

hot water storage systems are installed where discharges from safety devices may not be apparent i.e. in dwellings

occupied by blind, infirm or disabled people, consideration should be given to the installation of an electronically

operated device to warn when discharge takes place.

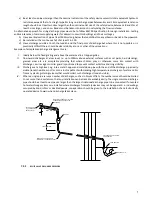

7.2.2

RELIEF VALVE DISCHARGE PIPEWORK

TUNDISH

METAL DISCHARGE PIPE (D1) FROM

TEMPERATURE RELIEF VALVE

TO TUNDISH

SAFETY DEVICE

(e.g. TEMPERATURE

RELIEF VALVE)

DISCHARGE PIPE (D2) FROM

TUNDISH, WITH CONTINUOUS FALL

FIXED GRATING

TRAPPED GULLY

DISCHARGE IDEALLY BELOW

FIXED GRATING

300mm MINIMUM

600mm MAXIMUM