Subject

to

change

without

notice

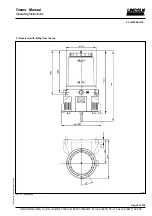

Owner Manual

Operating Instructions

2.1A-30004-A02

LINCOLN GmbH & Co. KG Postfach 1263 D-69183 Walldorf Tel +49 (6227) 33-0 Fax +49 (6227) 33-259

Page 23 of 36

Remedy:

* Remove main line towards the monitored divider valve.

* Unscrew and check piston detector by introducing a

iron

pin

into the borehole of the detector,

maintain it there for

more than 2 seconds and pull out again.

If then the

pump switches off, a blockage may exist; if the pump

does not switch off, check cable connections towards the

pump. If necessary, replace piston detector with connec-

ting plug.

* Check cable connections towards pump. If necessary,

replace piston detector with connecting plug.

* Exchange printed circuit board.

Troubleshooting

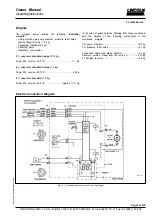

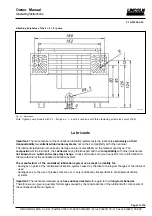

Pump 233

4209a99

The circulating segment in the display of the membrane

key pad indicates that the pump operates properly.

Fault: Pump motor does not run; stirring paddle does not turn

Cause:

Power supply interrupted. Segment display for On/h is

not lit.

*

Check the voltage supply to the pump/

fuses. If necessary, eliminate the fault or

replace the fuses.

*

Check the feed line from the fuses to the

plug of the pump and then to the printed

circuit board.

*

Trigger an additional lube cycle. Check

voltage supply from the p.c.b. to the motor, if

necessary replace motor.

* Replace p.c.b.

*

*EP*

display is lit. Replace housing and

membrane key pad.

Remedy:

Power supply from printed circuit board to motor inter-

rupted. Electric motor defective.

Printed circuit board defective.

Key on membrane key pad defective.

Fault: Pump does not deliver lubricant

Cause:

Reservoir empty.

* LL *

display on the membrane key

pad is flashing.

Pump does not deliver lubricant and

*Er *

display on the

membrane key pad is flashing.

Air pockets in the lubricant.

Improper lubricant has been used.

Suction hole of pump element clogged.

Pump piston is worn.

Check valve in pump element defective or clogged.

Remedy:

* Fill up the reservoir with clean grease. Let the pump run

(trigger additional lube cycle) until the lubricant shows at

all lube points.

NOTE: Dependent on the ambient temperature and/ or type

of lubricant. the pump element needs a longer run time to

reach the full output capacity. Therefore, trigger several addi-

tional lube cycles.

*

Trigger several additional lube cycles. Lubricant must be

dispensed without air bubbles (towards the lube point).

*

Change lubricant. Consider table of lubricants.

*

Remove pump element. Check suction hole for foreign

particles. If there are any, remove them.

*

Replace pump element.

*

Replace pump element.

Cause:

Piston detector (initiator) defective.

Blockage in the system

Cable connections from the piston detector towards the

pump interrupted.

Printed circuit board defective.

Pump motor does not stop dispensing (30 minutes monitoring time)