Subject

to

change

without

notice

Owner Manual

Operating Instructions

2.1A-30004-A02

Page 14 of 36

LINCOLN GmbH & Co. KG Postfach 1263 D-69183 Walldorf Tel +49 (6227) 33-0 Fax +49 (6227) 33-259

00002634

Fig. 20 - Piston detector

Operating time

A

piston detector

(initiator) which has been installed on

a metering device instead of a piston closure plug,

monitors and brings the pump

operating time

to a close

after all the pistons of this metering device have dispen-

sed their lubricant quantity once.

The operating time depends on the systems lubricant

requirement and on the location of the piston detector

(either on the main metering device or on the secondary

metering device).

During the pump operating time a circulating segment

appears in the display of the membrane key pad (see

Display of the membrane key pad).

After an interruption of the operating time, e.g. by

switching off the power supply, the operating time

continues from the point where it had been interrupted.

When the machine contact or the driving switch is

switched off, the pause times which have already

elapsed are stored and added up by an

electronic data

memory

(EEPROM) until the piston detector stops the

operating time.

Monitoring time

Note: Only one lubrication cycle can be monitored.

A fixed

monitoring time

of a maximum of 30 minutes runs

in parallel to the operating time.

Note: Normally, the monitoring time ends at the same time

as the operating time.

If there is

no switching off signal

from the piston detector

(fig. 20) to the printed circuit board within 30 minutes

a

fault signal

will occur (see Display of the membrane key

pad).

An external

signal lamp

flashes

continuously

in case of a

fault.

20002458

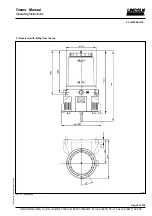

Fig. 21 - External triggering of an additional lubrication

* Press pushbutton for more than 2 seconds.

External triggering of additional lubrication