Subject

to

change

without

notice

Owner Manual

Operating Instructions

2.1A-30004-A02

LINCOLN GmbH & Co. KG Postfach 1263 D-69183 Walldorf Tel +49 (6227) 33-0 Fax +49 (6227) 33-259

Page 11 of 36

4159a98

Fig. 12 - Sectional view: Adjustable pump element

1 - Adjusting spindle SW 16 (with over flats)

3 - Pump element body

6 - Control piston

2 - Counter nut SW 24

4 - Gasket

7 - Delivery piston

5 - Pump cylinder

S - Size

Setting of the output

* Unscrew the coupling nut for fixing the pressure relief

valve.

* Loosen counter nut (2, fig. 12) while holding in position

pump element body (3) by means of a second wrench.

* Adjust the regulating spindle (1) by means of a wrench,

see output diagram (fig. 13)

* The size S (see fig. 12) for the desired lubricant output

can be ascertained by using the delivery diagram shown

in fig. 13.

Retrofit adjustment of maximum lubricant output:

Note: In order to ensure that the lubricant output setting will

be as exact as possible, first the actual size S of the max.

lubricant output must be ascertained as follows. The measu-

red difference to the nominal value 29 mm must be conside-

red for all other setting values (e.g. ± 0,1).

* Unscrew the adjusting spindle (1, fig.12) out of the pump

element body (3) until S is approx. 30 mm.

* Screw counter nut (2) onto stop collar of the adjusting

spindle (1).

* Screw adjusting spindle (1) with counter nut (2) into

pump body (3) until stop.

Adjustment of small lubricant output:

* Before the pump element can be adjusted to a small

lubricant output, the size S for max. lubricant output

must be ascertained, and the difference to the nominal

value 29 mm must be transferred to any desired setting

between 25.5...28.5 mm.

* Dimension S must be adjusted to the desired value in

accordance with the delivery diagram (fig. 13).

Note: At maximum setting, S is 29±0.1 mm.

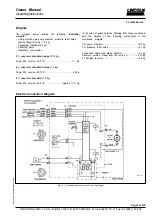

Fig. 13 - Delivery diagram

4179a99

A - Lubricant output in cm³/minS - Size

B - Lubricant output in cm³/stroke