Subject

to

change

without

notice

Owner Manual

Operating Instructions

2.1A-30004-A02

LINCOLN GmbH & Co. KG Postfach 1263 D-69183 Walldorf Tel +49 (6227) 33-0 Fax +49 (6227) 33-259

Page 13 of 36

10032618

Fig. 17 - Return line connection

Lubricant quantities which cannot be dispensed by the

metering device must be returned to the pump via the

return line connection (fig. 15).

Return Line Connection

Printed circuit board with data memory

1059a95

Fig. 18 - Time sequence diagram

tB - Working hours

T - Lubrication cycle

tP - Individual pause times

T1 - Stored pause times

T2 - Operating times

The printed circuit board automatically controls the

sequence of the pause and operating times of the 233

centralized lubrication pump as a function of the vehicle

or machine working hours tB (fig. 18).

The sequence of the pause and operating times is

activated when the machine contact or driving switch is

switched on, i.e. the centralized lubrication pump is ready

for operation.

A lubrication cycle consists of one pause time and one

operating time. Once the pause time has elapsed, the

operating time starts to run. This lubrication cycle is

repeated permanently after the machine or vehicle has

been put into operation (fig. 18).

During the operating time the pump element dispenses

the lubricant to the lubrication points via progressive

divider valves.

4205a01

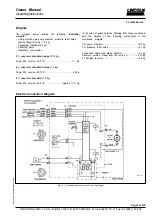

Fig. 19 - Pump 233 with data logger, schematic drawing

1 - Low-level control 4 - Control p.c.b. with data logger

2 - Piston detector 5 - Pump

3 - Membrane key pad 6 - Lubricant divider valve SSV N

Pause time

The pause time

- determines the frequency of the lubrication cycles within

a working cycle;

- is started and stopped via the machine contact or driving

switch

- is adjustable

When the machine contact or the driving switch is

switched off, the pause times which have already elap-

sed are stored and added up by an

electronic data

memory

(EEPROM) until the time which has been set on

the membrane key pad is reached.

After the machine contact or driving switch is switched on

again, the printed circuit board operates from the point

where it had been interrupted.

If the setting is modified within the pause time, the

printed circuit board takes over the new value

automatically on completion of the programming

procedure (see Programming Mode).

The pause time setting may be different for each applica-

tion. It must be adjusted in accordance with the respecti-

ve lubrication cycles (see Programming Mode).

Standard setting: 6 hours.