Subject

to

change

without

notice

Owner Manual

Operating Instructions

2.1A-30004-A02

Page 16 of 36

LINCOLN GmbH & Co. KG Postfach 1263 D-69183 Walldorf Tel +49 (6227) 33-0 Fax +49 (6227) 33-259

4228a01

In this case, switch on the pump by pressing the key for

additional lubrication (fig. 25). Acknowledge the mal-

function before doing so.

When a malfunction is present, it can only be cancelled

by triggering an additional lubrication and after a proper

lubrication cycle has been executed.

If the fault is still present after an additional lube cycle

has been triggered, the fault signal

* ER *

is again

displayed in the display of the membrane key pad.

The monitoring time starts at the same time as the

operating time. It is a fixed time of 30 minutes.

If the voltage supply is interrupted during the monitoring

phase (operating time), the monitoring time starts from

the beginning after the pump has been switched on

again.

Acknowleding the malfunction

On pressing the key (fig. 28), the flashing display

* Er *

changes into a continuous light.

An external signal lamp switches off.

Low-level indication

When the reservoir is empty the display on the

membrane key pad shows the flashing fault signal

*LL *.

The function of the low-level control is described on page

17.

In the case of a low-level indication the pump does not

switch off immediately. The current lube cycle is

completed. Upon expiration of the pause time, the pump

cannot be started automatically again. The flashing

indication

* LL*

appears on the display of the membrane

key pad (fig. 29)

.

* Before filling the reservoir, press the key, fig. 30, to

acknowledge the low-level indication.

* Fill pump and trigger additional lubrication. As soon as

the additional lube cycle has been triggered, the

LL

display is cancelled. The automatic lube cycle resumes.

Acknowleding the low-level indication

By pressing the key (fig. 30) the flashing light

* LL *

is

changed into a continuous light (fig. 31).

An external signal lamp switches off.

Malfunction/ low-level indication

If both indications occur at the same time, then both

displays

* Er *

and

* LL*

will flash alternately.

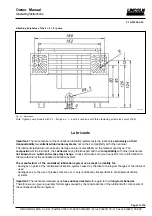

Fig. 27 - Membrane key pad with fault signal

Fig. 28 - Acknowledging a flashing fault signal Er

4214a99

4211a99

Fig. 29 - Display of a low-level indication

4214a99

Fig. 30 - Acknowledging a flashing fault signal LL

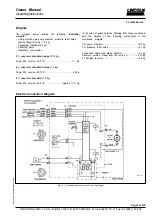

Monitoring relay (on the control p.c.b.)

The monitoring relay signalizes a low-level indication or a

malfunction. In both cases, the monitoring relay will pick

up. Via a minus potential contact, a signal lamp can be

used as external fault indication which has to be

switched against plus. Whenever the fault indication is

acknowledged, the flashing indication switches to a

continuous indication.

Note: If the fault has not been put in order properly, after

switching the pump off and on, an acknowledged fault/ low-

level indication will appear as a flashing indication in the

display window again.

Fig. 31 - Acknowledged fault signal LL