Page Number 18 of 28

QLS 311

Subject

to

modifications

2.1B-38008-A01

Form 403074

Installation and Operation Instructions

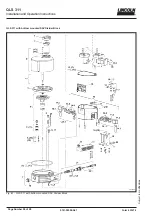

Fault: Blockage in the downstream progressive system (Continued)

Cause:

Divider valve is blocked

Remedy:

* Replace the divider block or clean it as follows.

* Remove all threaded tube fittings.

* Unscrew the piston closure plugs.

* Remove the piston, if possible, with a soft mandrel

(smaller than ø 6 mm, 0.24 in).

Important

: The pistons are individually fitted in the bore

holes of the divider block. After removing the pistons, mark

them in order to reinstall them in the right direction and

position. They may not be interchanged.

* Thoroughly clean the divider block body in a

grease desolving detergent and dry them out with

compressed air.

* Clean through the material passages (ø 1.5 mm, 0.59

in) at the thread ends of the piston bore holes using of a

pin.

* Clean the divider block once more and dry it thoroughly.

* Reassemble the divider block.

Fault: Differing lubricant amounts at the lubrication point

Cause:

Lubricant metering is not correct.

Setting of the pause time is incorrect.

Remedy:

*

Check the lubricant metering according to the lubricati-

on chart.

*

Check time setting.