Subject

to

modifications

Page Number 15 of 28

2.1B-38008-A01

QLS 311

Form 403074

Installation and Operation Instructions

Maintenance

To fill reservoir

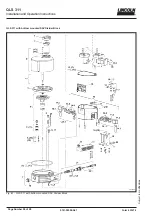

Fig. 30 - Filling reservoir

Repair

Functional Test

Fig. 31 - Push button for an additional lubrication cycle

Maintenance, Repair and Tests

Maintenance is essentially limited to refilling the reservoir

with clean lubricant as necessary. However, check

regularly (every two weeks) whether the lubricant is being

dispensed to all the lubrication points.

Also check the feed lines for damage and replace them, if

necessary.

Switch off the voltage supply for pumps 120 VAC and 230

VAC before servicing the pump.

For repair work on the QLS 311 only use Lincoln Industri-

al original spare parts.

Using non-Lincoln Industrial parts will void the pump

warranty.

Turn off the voltage supply for pumps 120 VAC and 230 VAC

before servicing the pump.

Important:

To clean the system, use petroleum spirit or

petroleum.

Do not use Tri, Per or similar solvents or polar

or organic solvents such as alcohol, methanol, acetone,

etc.

Note: Whenever work is performed on the centralized

lubrication system, special attention should be paid to

cleanliness. Dirt will cause system failure.

Fill the reservoir up to the Max. mark via the cover.

Important:

The oil must be free from impurities and must

not change its consistency over the course of time.

Note: If the reservoir has been completely emptied, the

pump may require priming and a longer running time to re-

ach the full lubricant output. Therefore, initate additional lube

cycles

manually.

* Press push button to initiate a

lubrication cycle.

4222a99

* By operating the drive motor without the reservoir

installed, there is a risk of injury by eccentric gear.

4262a00