Page Number 16 of 28

QLS 311

Subject

to

modifications

2.1B-38008-A01

Form 403074

Installation and Operation Instructions

Troubleshooting

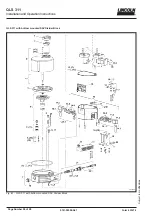

Pump of the QLS 311 system

Fault: pump motor doesnt run

Cause:

Power supply interrupted. Green decimal point On/h on

display is not lit.

* Check the voltage supply to the pump/

fuses. If necessary, eliminate the fault or

replace the fuses.

* Check the feed line from the fuses to the

plug of the pump and then to the printed

circuit board.

*

Initiate an additional lube cycle. Check

voltage supply from the printed circuit

board to the motor.

* Replace printed circuit board.

* Replace housing with key pad.

Remedy:

Power supply from printed circuit board to motor

interrupted.

Printed circuit board defective.

Key pad or button is defective.

EP

display at the key

pad flashes.

Fault: pump does not deliver lubricant

Cause:

Reservoir is almost empty.

LL

display at the key pad is

flashing.

Pump lost prime and

Er

display at the key pad is

flashing.

Air pockets in lubricant.

Improper lubricant has been used.

Suction hole of pump element clogged.

Pump piston is worn.

Check valve in pump element defective or clogged.

Remedy:

* Fill the reservoir with clean grease. Let the pump run

(initiate an additional lube cycle) until the lubricant

shows at all lube points.

Note: According to the ambient temperature and/or sort of

lubricant, the pump element needs no longer operation

time in order to reach the full pump capacity. Therefore, in-

iate several additional lube cycles.

*

Trigger an additional lubrication cycle. Lubricant must

dispense without air bubbles.

*

Change the lubricant.

*

Remove pump element. Check suction hole for foreign

particles. If there are any, remove them.

*

Replace pump element.

*

Replace pump element.

The green rotating display indicates that the pump

operates properly.

4209a99

Fault: Pump either does not switch off at all or only after the monitoring time of 15 min.

Cause:

Proximity switch is not dampened, i.e. the control pin

does not move within the switching range of the initiator,

or the distance between the control pin and the initiator

surface is more than 0.5 mm (0.02 in.).

Remedy:

* Initiate an additional lubrication. Check whether the

control pin moves centrically over the switching surface

of the initiator. In case the adjustments do not

correspond to the indications, the fixing position of the

metering device has to be corrected.

* Check the distance between the control pin and the

switching surface of the initiator (max. 0.5 mm; 0.02 in.).

In case the adjustments do not correspond to the

indications, the fixing position of the proximity switch

has to be corrected.

* Distances between the switching surface of the initiator

and the upper edge of the fixing nut:

* When the metering device is mounted at the back: 16

/

0,2 mm (0.62/-0.08 in.)

* When the metering device is mounted at the bottom:

12,7 +/0,1 mm (0.5 +/-0.004 in.).

* Tightening torque of the nut: 1,5 Nm (1.10 ft-lb).