A-3

INSTALLATION

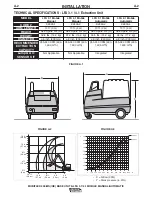

MOBIFLEX 400-MS(/HE) BASE UNIT & LFA 3.1/4.1 MOBILE MANUAL/AUTOMATIC

A-3

READ ENTIRE INSTALLATION SECTION BEFORE

STARTING INSTALLATION.

SAFETY PRECAUTIONS

GENERAL DESCRIPTION

This instruction manual describes two base units and

four types of extraction arms & one hose:

- K1741-1 Mobiflex 400-MS Base Unit (mobile filter

unit with self-cleaning filter cartridge - filter class

MERV 11 (untreated); MERV 15 (treated)

- K1741-2 Mobiflex 400-MS/HE Base Unit (mobile filter

unit with high efficiency self-cleaning filter cartridge -

filter class MERV 16)

- K2633-1 LFA 3.1 Mobile Manual (10 ft. extraction

arm)

- K2633-3 LFA 4.1 Mobile Manual (13 ft. extraction

arm)

- K2633-2 LFA 3.1 Mobile Automatic (10 ft. extraction

arm with integrated Lamp & Arc Sensor Kit)

- K2633-4 LFA 4.1 Mobile Automatic (13 ft. extraction

arm with integrated Lamp & Arc Sensor Kit)

- K1668-3 Hose & Hood Set

MOBIFLEX 400-MS BASE UNIT

The K1741-1 Mobiflex 400-MS Base Unit is a mobile

filter unit with integrated fan that provides extraction

and filtration for use with a flexible extraction arm or

optional hose.

The Mobiflex 400-MS Base Unit features a steel mesh

prefilter and a round cellulose LongLife filter cartridge.

This LongLife filter cartridge is provided with a precoat

(ExtraCoat) to extend the lifespan and increase initial

operating efficiency of the filter.

The Mobiflex 400-MS Base Unit is provided with a

RotaPulse system for automatic cleaning of the

LongLife filter cartridge.

The Mobiflex 400-MS is a portable unit suitable to be

used in relatively small facilities or near sources of pol-

lution without a fixed location.

The Mobiflex 400-MS Base Unit with Flexible

Extraction Arm is used for extracting and filtering fume

which is released during the most common welding

processes, such as:

• MIG/MAG solid wire (GMAW)

• MIG/MAG flux cored wire (FCAW)

• TIG (GTAW) welding

• Stick welding (MMA or SMAW)

• Autogeneous welding

The Mobiflex 400-MS is designed for intermittent or

continuous welding applications as indicated above.

The Mobiflex 400-MS filter is recommended for annual

consumable use of approximately:

• 6,000 lbs (2,750 kg) GMAW or FCAW or GTAW

• 4,000 lbs (1,800 kg) MMA or SMAW or autoge-

neous

Variables such as coatings (e.g. oil), base material,

weld process, humidity and procedures can affect filter

life and performance.

MOBIFLEX 400-MS/HE BASE UNIT

The K1741-2 Mobiflex 400-MS/HE Base Unit is a

mobile filter unit with integrated fan that provides

extraction and filtration for use with a flexible extraction

arm or optional hose.

The Mobiflex 400-MS/HE Base Unit features a steel

mesh prefilter and a high efficiency round

cellulose/polyester blend LongLife filter cartridge.

The Mobiflex 400-MS/HE Base Unit is provided with a

RotaPulse system for automatic cleaning of the

LongLife filter cartridge.

The Mobiflex 400-MS/HE is a portable unit suitable to

be used in relatively small facilities or near sources of

pollution without a fixed location.

The Mobiflex 400-MS/HE Base Unit with Flexible

Extraction Arm is used for extracting and filtering fume

which is released during the most common welding

processes, such as:

• MIG/MAG solid wire (GMAW)

• MIG/MAG flux cored wire (FCAW)

• TIG (GTAW) welding

• Stick welding (MMA or SMAW)

• Autogeneous welding

ELECTRIC SHOCK can kill.

•

Only qualified personnel should per-

form this installation.

• Turn the input power OFF and unplug

the machine from the receptacle before

working on this equipment.

• Insulate yourself from the work and ground.

• Always connect the machine to a power supply

grounded according to the National Electrical Code

and local codes.

WARNING