B-5

OPERATION

B-5

MOBIFLEX 400-MS(/HE) & LFA 3.1/4.1

MOBILE AUTOMATIC

See Figure B.2

and Figure B.4

• Press the power switch ON (

See Figure B.2 item B

)

to turn power to the unit.

• Using the handle (See Figure B.4 item A), position

the hood of the extraction arm in the desired position

at approximately 6-12 inch (15-30 cm) from the

source of fume.

• If desired: turn on the halogen lamp using on/off

switch (See Figure B.4 item C).

• Open the throttle valve (See Figure B.4 item B).

• Start welding.

Due to the built-in Arc Sensor, the machine will start

automatically. After finishing welding, the machine will

automatically stop after approximately 20 seconds.

• Press the power switch OFF (

See Figure B.2 item A

)

to interrupt power supply.

MOBIFLEX 400-MS(/HE) & LFA 3.1/4.1

MOBILE AUTOMATIC (MANUAL START)

Manual start of the Lamp & Arc Sensor Kit is recom-

mended for TIG welding or in case the Arc Sensor is

unable to detect the arc due to weld position.

* UV from TIG welding is less than other weld process-

es resulting in arc sensor perhaps not detecting weld.

See Figure B.2

and Figure B.4

• Press the power switch ON (

See Figure B.2 item B

)

to turn power to the unit on.

• Using the handle (See Figure B.4 item A), position

the hood of the extraction arm in the desired position

at approximately 6-12 inch (15-30 cm) from the

source of fume.

• If desired: turn on the halogen lamp using on/off

switch (See Figure B.4 item C).

• Open the throttle valve (See Figure B.4 item B).

• Turn on the machine using the on/off switch (See

Figure B.4 item D).

• Start welding.

• Turn off the machine approximately 20 seconds after

finishing welding using the on/off switch (See Figure

B.4 item D).

• Press the power switch OFF (

See Figure B.2 item A

)

to interrupt power supply.

AUTOMATIC FILTER CLEANING

SYSTEM

CONTROL LIGHT:

CLEANING

During normal operation (i.e. with a clean, non-saturat-

ed filter cartridge), the Mobiflex 400-MS(/HE) functions

automatically. As soon as a minimum airflow has been

reached as a result of the clogging, the pressure dif-

ference switch activates the RotaPulse compressed air

cleaning system which subsequently cleans the filter

using controlled jets of compressed air. The particulate

then falls into the dust tray.

During the automatic cleaning process the control light

(

See Figure B.2 item D

) is on (“CLEANING”). The

cleaning system stops when the airflow is sufficient

again.

This procedure is called online cleaning.

When no welding takes place for the automatic clean-

ing process, the fan will start running for 30 seconds

after every four compressed airjets to check the pres-

sure difference. This happens 15 times maximum.

When the airflow hasnʼt reached the required airflow

rate after 60 compressed airjets, the control light will

change into the “ALARM” mode.

• In this case, proceed with Control light: ALARM pro-

cedure.

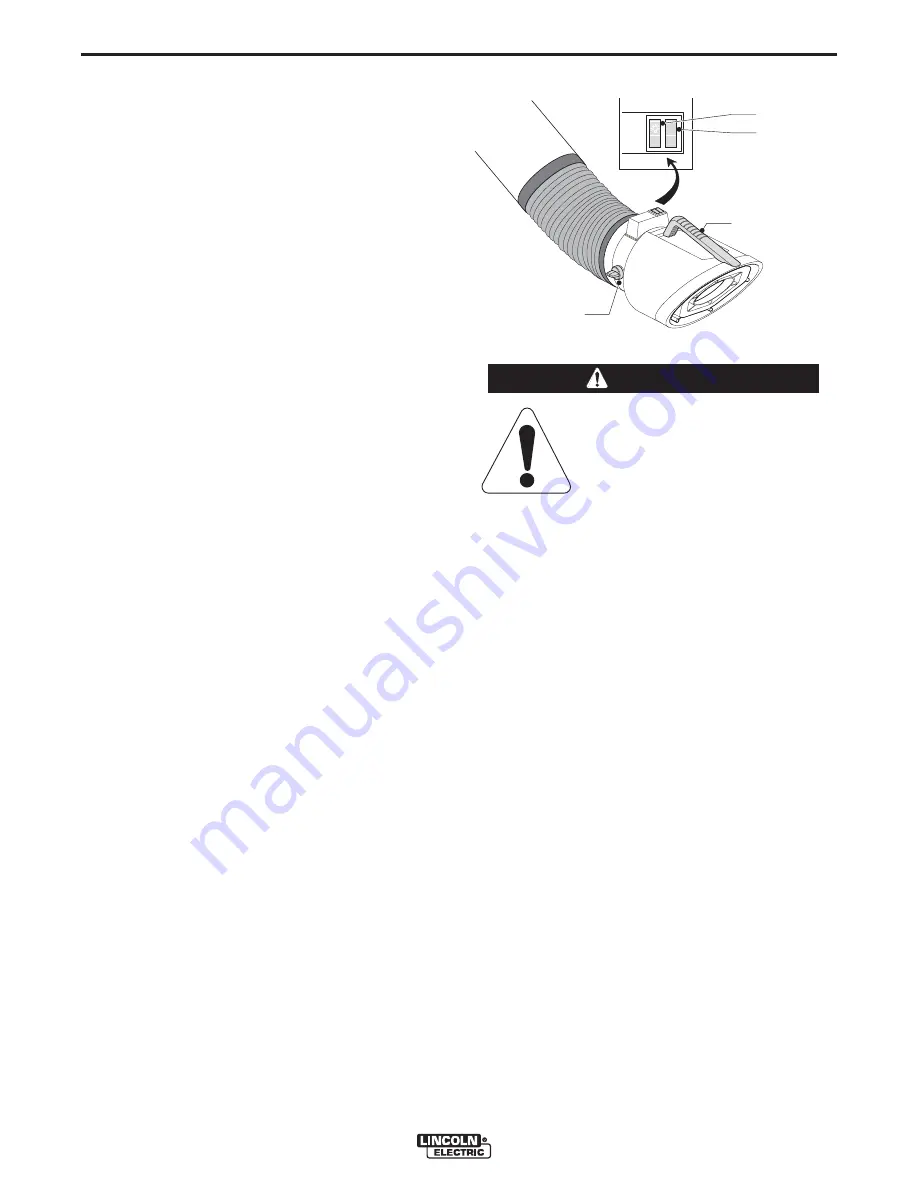

MOBIFLEX 400-MS(/HE) BASE UNIT & LFA 3.1/4.1 MOBILE MANUAL/AUTOMATIC

FIGURE B.4

I

O

C

D

B

A

Due to the parallel connection,

extraction fan on / off can be

arranged in three different ways:

• Automatically by Arc Sensor

• Manually by on/off switch at the

hood of the extraction arm

• Manually by push button switch fan on/off on the

machine

------------------------------------------------------------------------

ATTENTION