B-3

OPERATION

B-3

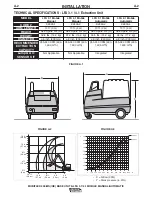

LFA 3.1/4.1 MOBILE

MANUAL/AUTOMATIC

The LFA 3.1/4.1 Mobile Manual and Mobile Automatic

Extraction Arms are flexible fume extraction arms with

a 360° rotatable hood. Incorporated into the arms hood

is a throttle valve that can be fully opened, partially

opened or completely closed to control airflow at hood

opening. The hood features an airflow focus vane,

which directs the air into the hood.

The armsʼ balance system increases its durability and

stability. As soon as the arms are raised, they are free

to move in any direction. Once the arms are posi-

tioned, they are fixed into place. This makes reposi-

tioning the arms simple, easy and effortless.

The extraction arms are made of solid, lightweight, 8

inch (203 mm) diameter dent and scratch resistant

tubes. They are provided with a spring balance system

for ultra-light, user friendly positioning of the arms.

The K2633-2 and K2633-4 LFA 3.1/4.1 Mobile

Automatic arms contains an integrated Lamp & Arc

Sensor Kit in the hood. The 35W/24V halogen lamp

provides additional light to the workpiece. With the use

of a delayed arc sensor, the extraction fan will operate

automatically. The automatic start/stop utilizes a 20

second auto stop to help conserve energy and reduce

noise level.

PRODUCT COMBINATIONS

In order to operate the Mobiflex 400-MS(/HE) Base

Unit, selection of following product is required:

• K2633-1 (1) LFA 3.1 Mobile Manual (10 ft. extraction

arm); or

• K2633-3 (1) LFA 4.1 Mobile Manual (13 ft. extraction

arm); or

• K2633-2 (1) LFA 3.1 Mobile Automatic (10 ft. extrac-

tion arm with integrated Lamp & Arc Sensor Kit); or

• K2633-4 (1) LFA 4.1 Mobile Automatic (13 ft. extrac-

tion arm with integrated Lamp & Arc Sensor Kit)

• K1668-3 (1) Hose and Hood Set instead of extraction

arm

OPERATION

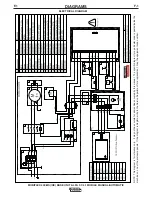

The air which contains welding fume is captured,

extracted and filtered, before being recirculated back

into the work environment. First, the welding fume is

extracted through an adjustable fume extraction arm

by the internal extraction fan.

Second, as the welding fume enters the Base Unit, it

passes through the prefilter. The prefilter separates

larger particles, debris and most sparks prior to the

welding fume entering the LongLife filter. Third, the air

passes from the outside through the LongLife filter car-

tridge. Fourth, after passing through the LongLife filter,

the filtered air exits the Mobiflex 400-MS(/HE) Base

Unit via the outlet grid at top of filter housing.

During use, an electronic pressure differential system

measures the static air pressure as it enters and exits

the filter cartridge. If the air pressure entering the filter

unit is greater than the air pressure exiting the filter

unit, the electronic circuit signals the internal cleaning

system to clean the filter cartridge. Compressed air

from the internal tank releases through multiple airjets

to clean one section of the filter cartridge at each air

burst. A complete cleaning cycle can be activated by

depressing a manual switch on the front of the control

panel. The particulate is blown off the filter cartridge

into a dust tray.

MOBIFLEX 400-MS(/HE) BASE UNIT & LFA 3.1/4.1 MOBILE MANUAL/AUTOMATIC

FIGURE B.1

Never use the Mobiflex 400-MS(/HE)

Base Unit without extraction arm or

Hose and Hood Set.

------------------------------------------------------------------------

ATTENTION

Worker exposure level should be

checked upon installation and peri-

odically thereafter to be certain it is

within applicable federal, state

and/or local regulations and guide-

lines (i.e. OSHA PEL and ACGIH

TLV limits in the U.S.).

------------------------------------------------------------------------

WARNING