B-4

OPERATION

B-4

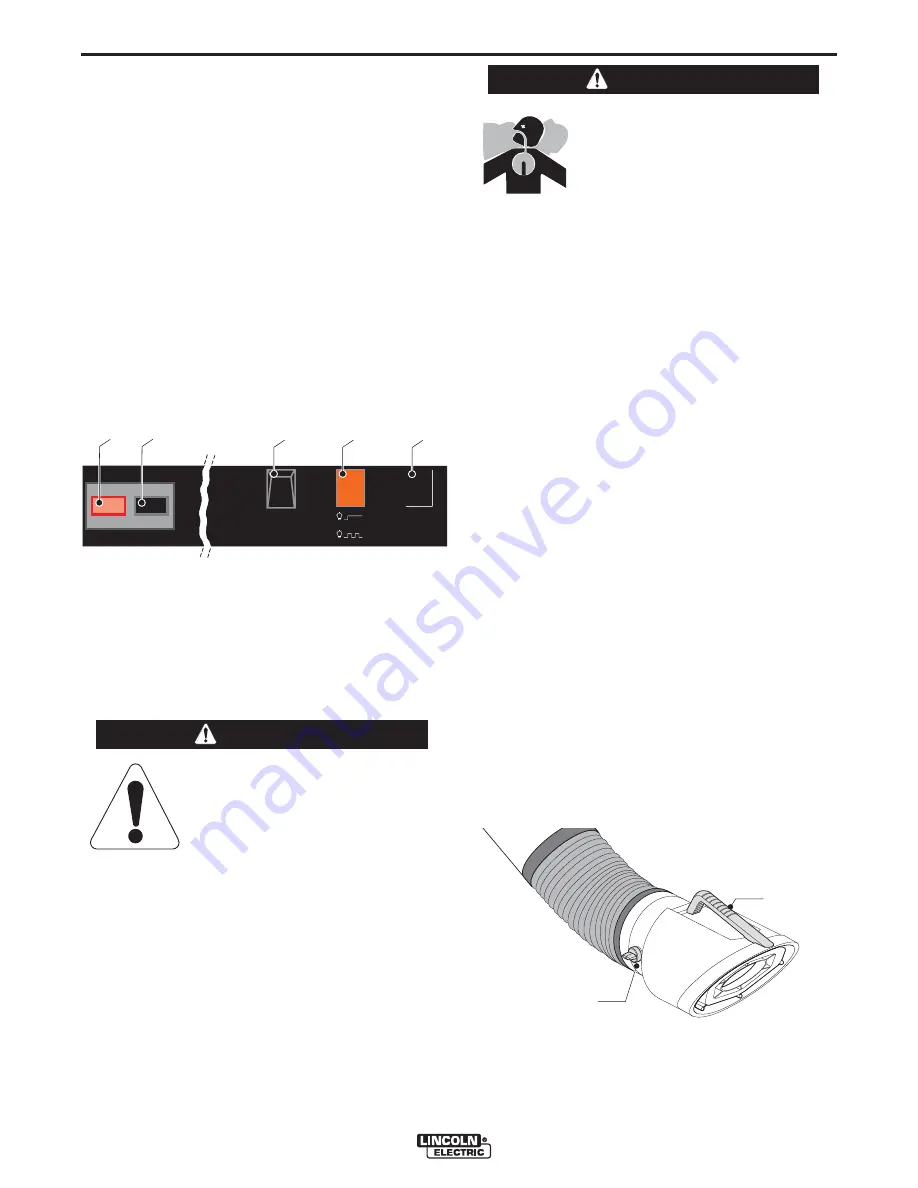

The control panel contains the following controls:

See Figure B.2

A. Power switch OFF

B. Power switch ON

C. FAN ON/OFF switch

D. Control light (orange)

- “CLEANING”: the control light is on indicating that

the machine is busy performing the (self-)clean-

ing process.

- “ALARM”: the control light blinks indicating that

the filter is saturated and cannot be cleaned suf-

ficiently in the automatic cleaning mode.

E. Filter cleaning ON/OFF - RESET button for off-line

cleaning and reset.

• Use the handles to move the Mobiflex 400-MS(/HE)

to the workplace.

• Lock the right swivel caster.

• Carefully apply the correct input power.

• Connect the Mobiflex 400-MS(/HE) Base Unit to com-

pressed air (

See Figure A.5 item Q

).

• Make sure the FAN ON/OFF switch (See Figure B.2

item C) is in the OFF position.

MOBIFLEX 400-MS(/HE) & LFA 3.1/4.1

MOBILE MANUAL

The hood of the extraction arm is provided with a han-

dle for easy positioning and a throttle valve for adjust-

ment of the airflow.

See Figure B.2 and Figure B.3

• Using the handle (See Figure B.3 item A), position

the hood of the extraction arm in the desired position

at approximately 6-12 inch (15-30 cm) from the

source of fume.

• Open the throttle valve (See Figure B.3 item B).

• Press the power switch ON (See Figure B.2 item B)

to turn power to the unit on.

• Turn on the FAN ON/OFF switch (See Figure B.2

item C) to start the machine.

• Start welding.

• Turn off the FAN ON/OFF switch approximately 20

seconds after finishing welding.

• Press the power switch OFF (See Figure B.2 item A)

to interrupt power supply.

MOBIFLEX 400-MS(/HE) BASE UNIT & LFA 3.1/4.1 MOBILE MANUAL/AUTOMATIC

FIGURE B.2

f

f

o

/

n

o

g

n

i

n

a

e

l

c

f

f

o

/

n

o

n

a

f

reset

cleaning

alarm

1

0

A

B

C

D

E

The compressed air should be dry

and oil-free according to ISO 8573-3

class 6.

------------------------------------------------------------------------

ATTENTION

The position of the hood should be

approximately 6-12 inch (15-30 cm)

in front of the welding arc.

Performance depends on factors

such as part vs. operator and weld

position, airflow (CFM and velocity

level), ambient conditions and

maintenance. Reposition hood as

needed to maintain efficient fume

capture.

------------------------------------------------------------------------

WARNING

FIGURE B.3

B

A