53

4.1.2. Setting

These setting instructions are meant as guideline and must not

always decelerate the machine to standstill before reaching the

undervoltage threshold. The parameter setting of the codes, which

influences the DC-bus control during mains failure detection (C079,

C080, C228, C236, C237), depend on the size of the drive

configurations and the mechanical features of the system.

There are minimum speeds at which the energy of the mechanical

system is not high enough to compensate the losses which occur

during the controlled deceleration (switched-mode power supplies,

inverter, machines).

Aim:

•

The aim is to have a controlled speed deceleration that allows a

DC-bus voltage value which remains higher than the

undervoltage threshold for as long as possible.

As soon as the value falls below this threshold, pulse inhibit will

be set and the drive will coast to standstill.

•

The brake chopper should not be activated during the controlled

deceleration of the speed.

Therefore, the parameter setting of the DC-bus control should

be "softly". It is not very important whether the DC-bus can be

loaded to the voltage set under C236.

Required measuring units:

•

Oscilloscope,

at least 2 channels, if possible with memory.

Test set-up:

•

Connect channel 1 of the oscilloscope with X5,62 of the axis

module (speed monitor).

•

Connect channel 2 of the oscilloscope with X3,2 of the supply

module (DC-bus monitor).

•

If available, connect channel 3 of the oscilloscope with X5,44 of

the axis module (RDY-output).

Presettings:

1. Set the speed controller of the axis module drive configuration

as usual.

2. Activate the mains failure detection of the master drive (C229 =

-1-).

If the function is activated, the RDY-output changes from the

HIGH level to the LOW level. As soon as the speed is

decelerated to 0, the RDY-output re-changes to HIGH.

3. The relevant codes must be set as follows:

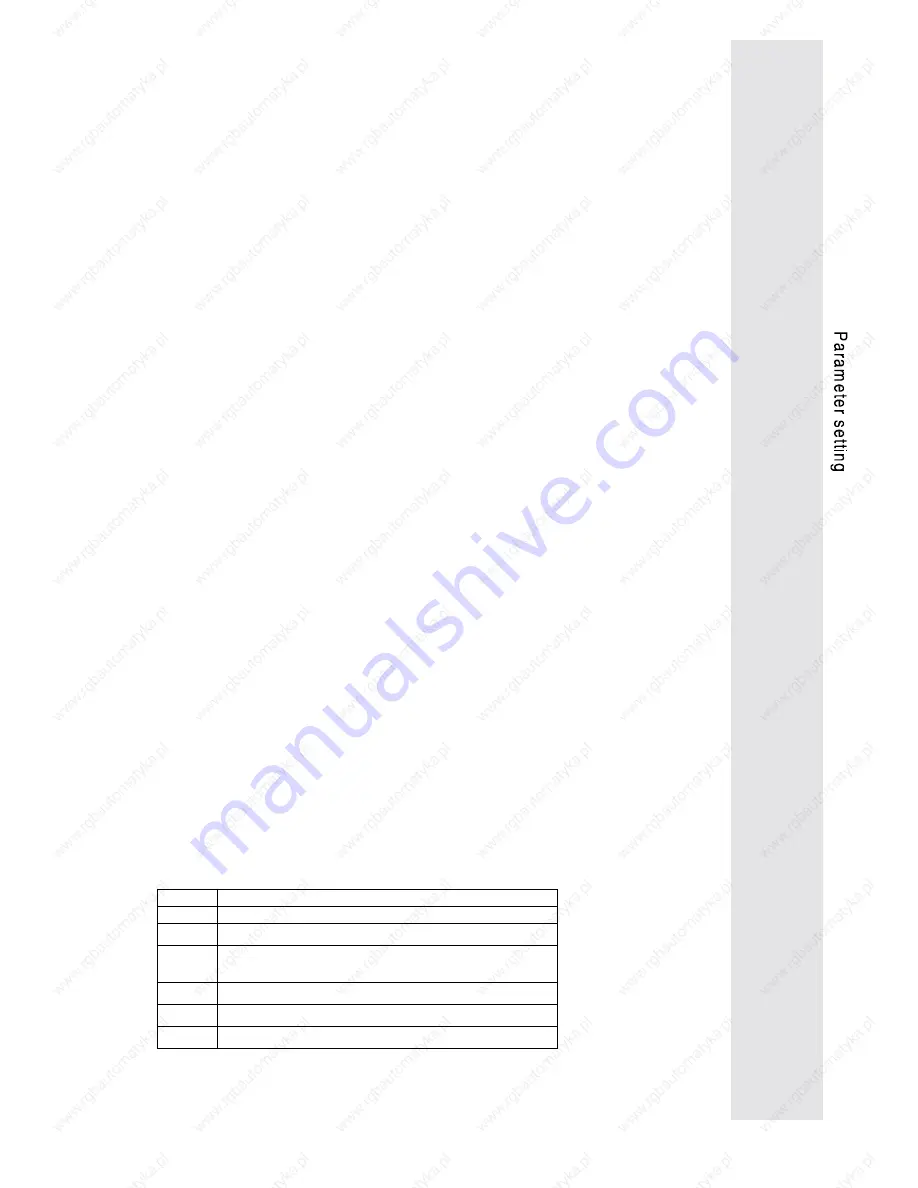

Code

Presetting

C079

-1-

C080

150 s

C228

1/10...1/20 of the natural slow-down time of the machine at

maximum operating speed

C229

-1-

C236

680 V

C237

1000 rpm or more

Summary of Contents for 9212

Page 3: ...EDB9200_E GB 00375316 Antriebstechnik Operating Instructions Servo controller 9200 series ...

Page 32: ...28 5 2 Wiring with positioning control SX 1 5 2 1 Diagram 1 Mains supply ...

Page 33: ...29 5 2 2 Diagram 2 Control circuit 230V ...

Page 34: ...30 5 2 3 Diagram 3 Control circuit 24V ...

Page 35: ...31 5 2 4 Diagram 4 Control connections 9200 SX1 Ω ...

Page 36: ...32 5 2 5 Diagram 5 Control connections SX1 ...