Page 29

TABLE 14

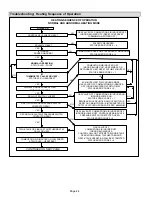

Cooling Mode Blower Speed Ramping

Ramping Option

Switch 9

Switch 10

A (Factory)

Off

Off

B

On

Off

C

Off

On

D

On

On

Ramping Option A (Factory Selection)

D

Motor runs at 50% for 30 seconds.

D

Motor then runs at 82% for approximately 7−1/2 minu-

tes.

D

If demand has not been satisfied after 7−1/2 minutes,

motor runs at 100% until demand is satisfied.

D

Once demand is met, motor runs at 50% for 30 sec-

onds then ramps down to stop.

OFF

OFF

1/2 MIN

50% CFM

COOLING DEMAND

7 1/2 MIN

82% CFM

100%

CFM

1/2 MIN

50% CFM

Ramping Option B

S

Motor runs at 82% for approximately 7−1/2 minutes. If

demand has not been satisfied after 7−1/2 minutes,

motor runs at 100% until demand is satisfied.

S

Once demand is met, motor ramps down to stop.

OFF

OFF

82%CFM

100% CFM

COOLING DEMAND

7 1/2 MIN

Ramping Option C

S

Motor runs at 100% until demand is satisfied.

S

Once demand is met, motor runs at 100% for 45 sec-

onds then ramps down to stop.

OFF

OFF

100% CFM

100% CFM

DEMAND

45 SEC.

Ramping Option D

S

Motor runs at 100% until demand is satisfied.

S

Once demand is met, motor ramps down to stop.

OFF

OFF

100% CFM

COOLING

DEMAND

Switches 11 and 12 −− Heating Mode Blower Speed −−

Switches 11 and 12 are used to select heating mode blower

motor speed. The unit is shipped from the factory with the

dip switches positioned for medium low (2) speed indoor

blower motor operation during the heating mode. The table

below provides the heating mode blower speeds that will

result from different switch settings. Refer to tables 16

through 25 for corresponding cfm values.

TABLE 15

Heating Mode Blower Speeds

Speed

Switch 11

Switch 12

1 − Low

On

On

2 − Medium Low

(Factory)

Off

On

3 − Medium High

On

Off

4 − High

Off

Off

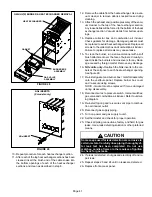

On−Board Link W914

On−board link W914, is a clippable connection between ter-

minals DS and R on the integrated control. W914 must be

cut when the furnace is installed with either the Harmony

III

t

zone control or a thermostat which features humidity

control. If the link is left intact the PMW signal from the Har-

mony III control will be blocked and also lead to control

damage. Refer to table 27 for operation sequence in ap-

plications including G60UHV, a thermostat which features

humidity control and a single−speed outdoor unit. Table 28

gives the operation sequence in applications with a two−

speed outdoor unit.

On−Board Link W951

On−board link W951 is a clippable connection between ter-

minals R and O on the integrated control. W951 must be cut

when the furnace is installed in applications which include a

heat pump unit and a thermostat which features dual fuel

use. If the link is left intact, terminal O" will remain ener-

gized eliminating the HEAT MODE in the heat pump.

On−Board Link W915

On−board link W915 is a clippable connection between ter-

minals Y1 and Y2 on the integrated control. W915 must be

cut if two−stage cooling will be used. If the link is not cut the

outdoor unit will operate in second−stage cooling only.

Status LEDs (SPEED, CFM, STATUS, E−COM)

The green SPEED LED indicates circulating blower speed

in response to the DS signal. The LED is lit during normal

blower operation and is off during a dehumidification de-

mand. In Harmony III applications, the brightness of the

LED indicates the requested blower speed.

The green CFM LED indicates the blower air flow. Count

the number of blinks between the two−second pauses to

determine the CFM. Each blink represents approximately

100 CFM.

The STATUS LED flashes diagnostic codes, which are de-

tailed on page 43.

The green E−COM LED indicates that the control is receiv-

ing and processing of commands and inputs. The LED may

flash rapidly or may display a single flash, depending upon

the activity.