Page 18

505361M 09/07

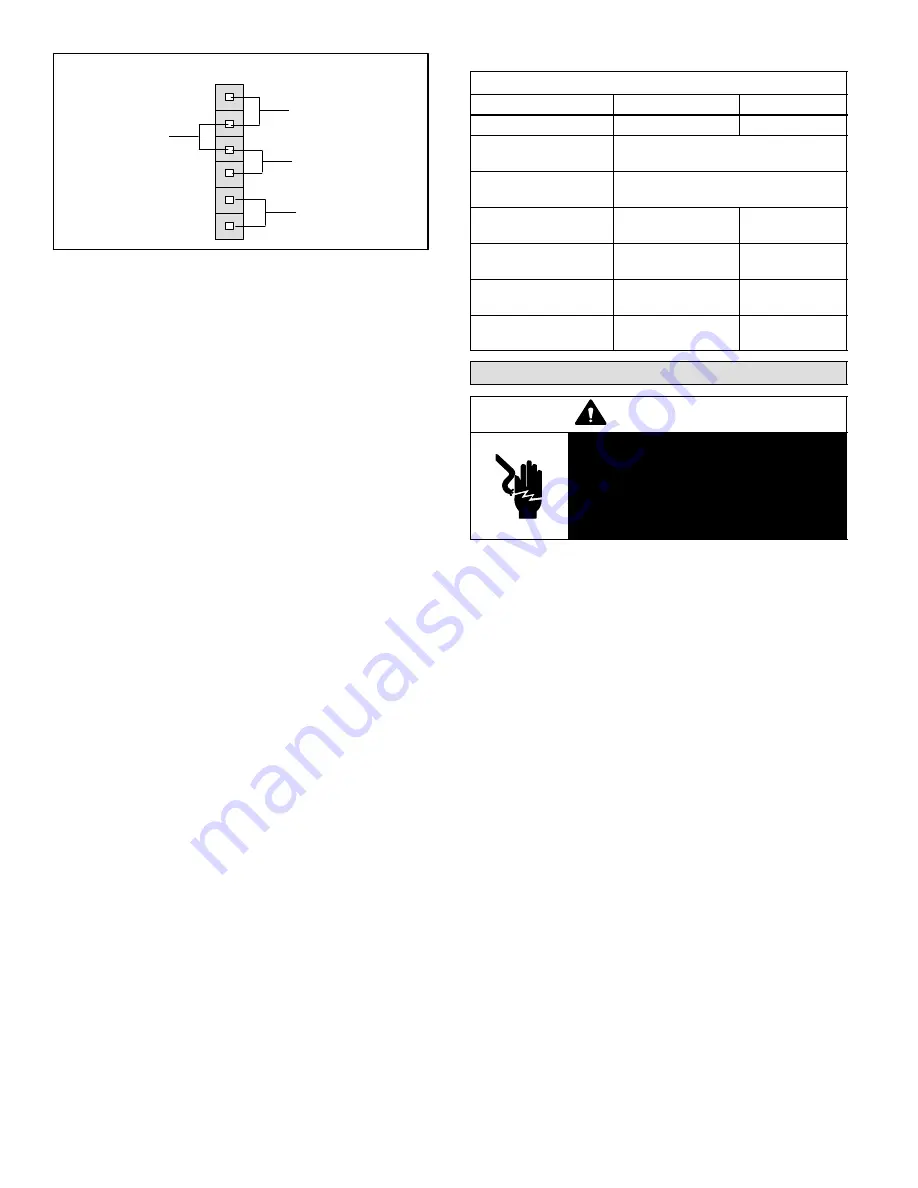

P1

TEST

90

DEFAULT

30

60

Figure 29. P1 Jumper Configurations

A TEST option is provided for troubleshooting.

The TEST

mode may be started any time the unit is in the heating

mode and the defrost thermostat is closed or

jumpered.

If the jumper is in the TEST position at power-up, the

control will ignore the test pins.

When the jumper is placed across the TEST pins for

two seconds, the control will enter the defrost mode.

If the jumper is removed before an additional 5−second

period has elapsed (7 seconds total), the unit will

remain in defrost mode until the defrost thermostat

opens or 14 minutes have passed.

If the jumper is not removed until after the additional

5−second period has elapsed, the defrost will

terminate and the test option will not function again

until the jumper is removed and re−applied.

P5 Compressor 30−Second Delay

The DCB has a field−selectable function to reduce

occasional sounds that may occur while the unit is cycling

in and out of the defrost mode. The compressor will be

cycled off for 30 seconds going in and out of the defrost

mode when the compressor delay jumper is removed.

NOTE − The 30-second OFF cycle is not functional when

jumpering the TEST pins.

Time Delay ByPass

The timed-off delay is five minutes long. The delay helps to

protect the compressor from short-cycling in case the

power to the unit is interrupted or a pressure switch opens.

The delay is bypassed by placing the timer select jumper

across the P1 TEST pins for 0.5 seconds as illustrated in

figure 29.

DS1 and DS2 Diagnostic LEDs

The DCB uses two LEDs (DS1 and DS2) for diagnostics.

The LEDs flash a specific sequence according to the

condition.

Table 10.

DS1 and DS2 LED Codes

Defrost Control Board Diagnostic LED

Mode

Green LED (DS2)

Red LED (DS1)

No power to control

OFF

OFF

Normal operation /

power to control

Simultaneous Slow FLASH

Anti-short cycle lock-

out

Alternating Slow FLASH

Low pressure switch

fault (Optional)

OFF

Slow FLASH

Low pressure switch

lockout (Optional)

OFF

ON

High pressure switch

fault (Optional)

Slow FLASH

OFF

High pressure switch

lockout (Optional)

ON

OFF

Maintenance

WARNING

Electric shock hazard. Can cause

injury or death. Before attempting to

perform any service or maintenance,

turn the electrical power to unit OFF at

disconnect switch(es). Unit may have

multiple power supplies.

Before the start of each heating and cooling season, the

following service checks should be performed by a

qualified service technician. First, turn off electrical power

to the unit prior to performing unit maintenance.

Inspect and clean the outdoor and indoor coils. The

outdoor coil may be flushed with a water hose.

NOTE − It may be necessary to flush the outdoor coil more

frequently if it is exposed to substances which are

corrosive or which block airflow across the coil (e.g., pet

urine, cottonwood seeds, etc.)

Visually inspect the refrigerant lines and coils for leaks.

Check wiring for loose connections.

Check voltage at the indoor and outdoor units (with

units operating).

Check the amperage draw at the outdoor fan motor,

compressor, and indoor blower motor. Values should

be compared with those given on unit nameplate.

Check, clean (or replace) indoor unit filters.

Check the refrigerant charge and gauge the system

pressures.