Page 9

HSXA16 SERIES

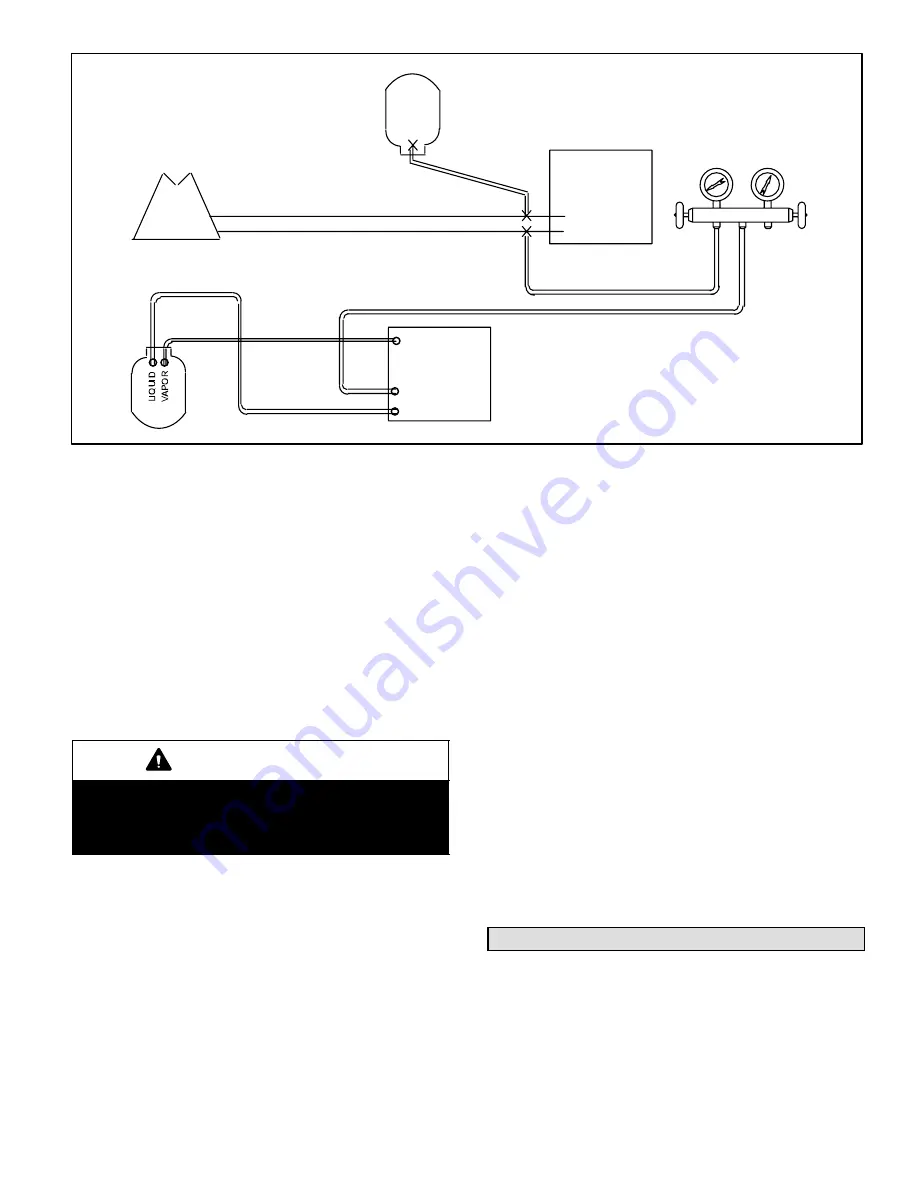

Flushing Connections

Low

Pressure

High

Pressure

Vapor Line

Service Valve

EXISTING

INDOOR COIL

HSXA16

UNIT

GAUGE MANIFOLD

Inverted HCFC−22 Cylin-

der

(Contains clean

HCFC−22 to be used for

flushing)

Liquid Line

Service Valve

Inlet

Discharge

Tank Return

Closed

Opened

EXISTING LIQUID LINE

RECOVERY CYLINDER

NOTE − The inverted HCFC−22 cyl-

inder must contain at least the

same amount of refrigerant as was

recovered from the existing sys-

tem.

Figure 10

EXISTING VAPOR LINE

RECOVERY MACHINE

2. Remove the existing outdoor unit. Set the new

HFC−410A unit and follow the brazing connection pro-

cedure which begins on the previous page to make line

set connections.

DO NOT install metering device at

this time.

Make low voltage and line voltage connections to the

new outdoor unit.

DO NOT turn on power to the unit

or open the outdoor unit service valves at this

time.

3. Remove the existing refrigerant flow control orifice or

thermostatic expansion valve before continuing with

flushing procedures. The existing devices are not ap-

proved for use with HFC−410A refrigerant and may

prevent proper flushing. Use a field−provided fitting to

reconnect the lines.

IMPORTANT

The line set and indoor coil must be flushed with

at least the same amount of clean refrigerant that

previously charged the system. Check the charge

in the flushing cylinder before proceeding.

4. Remove the pressure tap valve cores from the HSX-

A16 unit’s service valves. Connect an HCFC−22 cylin-

der with clean refrigerant to the vapor service valve.

Connect the HCFC−22 gauge set to the liquid line valve

and connect a recovery machine with an empty recov-

ery tank to the gauge set.

5. Set the recovery machine for liquid recovery and start

the recovery machine. Open the gauge set valves to

allow the recovery machine to pull a vacuum on the ex-

isting system line set and indoor coil.

6. Invert the cylinder of clean HCFC−22 and open its

valve to allow liquid refrigerant to flow into the system

through the vapor line valve. Allow the refrigerant to

pass from the cylinder and through the line set and the

indoor coil before it enters the recovery machine.

7. After all of the liquid refrigerant has been recovered,

switch the recovery machine to vapor recovery so that

all of the HCFC−22 vapor is recovered. Allow the re-

covery machine to pull a vacuum on the system.

NOTE − A single system flush should remove all of the

mineral oil from the existing refrigerant lines and in-

door coil. A second flushing may be done (using clean

refrigerant) if insufficient amounts of mineral oil were

removed during the first flush.

Each time the system

is flushed, you must allow the recovery machine

to pull a vacuum on the system at the end of the

procedure.

8. Close the valve on the inverted HCFC−22 drum and

the gauge set valves. Pump the remaining refrigerant

out of the recovery machine and turn the machine off.

9. Use dry nitrogen to break the vacuum on the refriger-

ant lines and indoor coil before removing the recovery

machine, gauges and HCFC−22 refrigerant drum. Re-

install pressure tap valve cores into HSXA16 service

valves.

10. Install the field−provided expansion valve (approved

for use with HFC−410A refrigerant) in the liquid line at

the indoor coil.

Manifold Gauge Set

Manifold gauge sets used with systems charged with

HFC−410A refrigerant must be capable of handling the

higher system operating pressures. The gauges should be

rated for use with pressures of 0 − 800 on the high side and

a low side of 30" vacuum to 250 psi with dampened speed

to 500 psi. Gauge hoses must be rated for use at up to 800

psi of pressure with a 4000 psi burst rating.