Page 7

HSXA16 SERIES

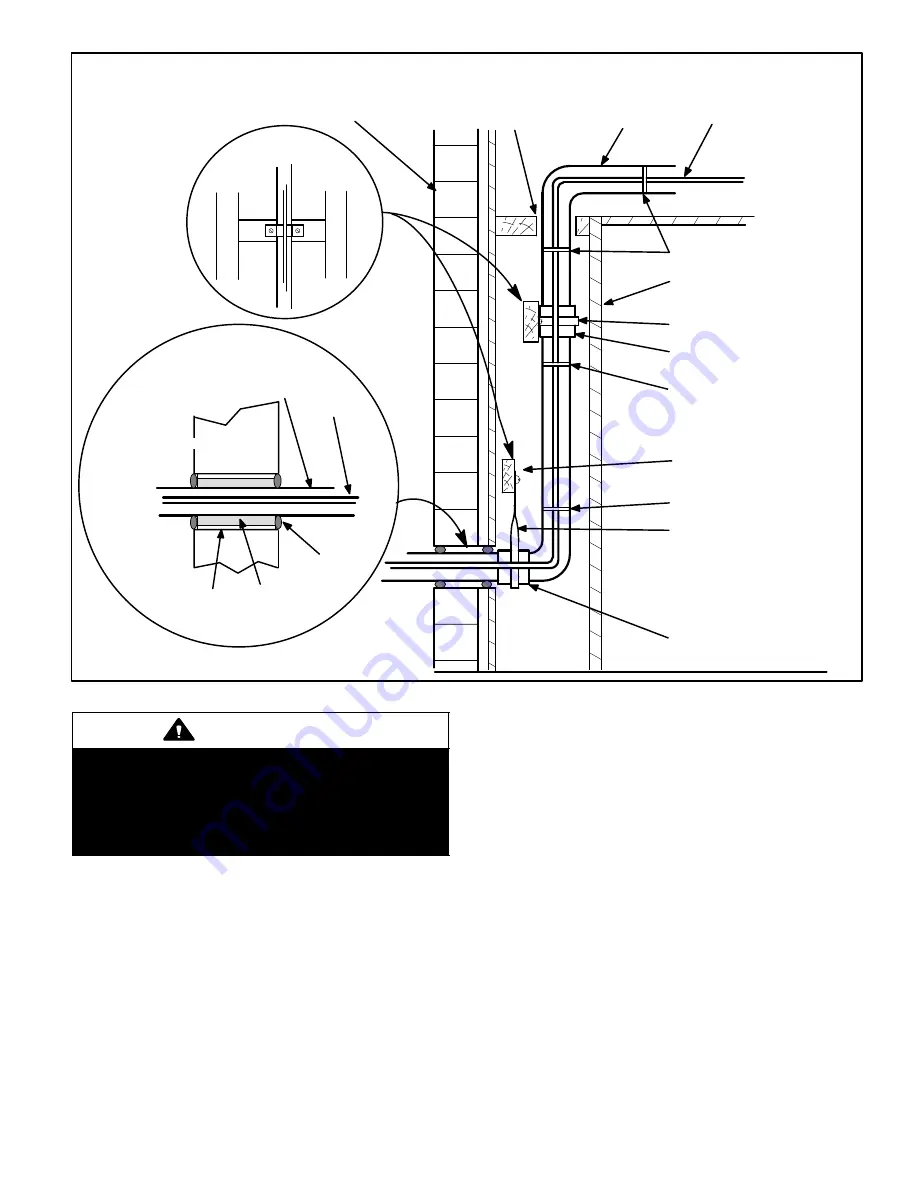

Refrigerant Line Sets: Installing Vertical Runs (new construction shown)

NOTE − Similar installation practices should be used if line set is to be installed on exterior of outside wall.

PVC PIPE

FIBERGLASS

INSULATION

CAULK

OUTSIDE WALL

VAPOR LINE WRAPPED

WITH ARMAFLEX LIQUID

LINE

IMPORTANT!

Refrigerant

lines must

not contact

structure.

OUTSIDE WALL

LIQUID LINE

VAPOR LINE

IMPORTANT - Refrigerant

lines must not contact wall.

WOOD BLOCK

BETWEEN STUDS

STRAP

SLEEVE

WOOD BLOCK

STRAP

SLEEVE

WIRE TIE

WIRE TIE

WIRE TIE

Figure 8

INSIDE WALL

WARNING

Polyol ester (POE) oils used with HFC−410A refrig-

erant absorb moisture very quickly. It is very im-

portant that the refrigerant system be kept closed

as much as possible. DO NOT remove line set caps

or service valve stub caps until you are ready to

make connections.

Brazing Connection Procedure

1. Cut ends of the refrigerant lines square (free from

nicks or dents). Debur the ends. The pipe must remain

round, do not pinch end of the line.

2. Before making line set connections, use dry nitrogen

to purge the refrigerant piping. This will help to prevent

oxidation and the introduction of moisture into the sys-

tem.

3. Use silver alloy brazing rods (5 or 6 percent

minimum

silver alloy for copper−to−copper brazing or 45 percent

silver alloy for copper−to−brass or copper−to−steel

brazing) which are rated for use with HFC−410A refrig-

erant. Wrap a wet cloth around the valve body and the

copper tube stub. Remove light maroon washers from

service valves and shield light maroon stickers in order

to protect them during brazing. Braze the line set to the

service valve.

4. Wrap a wet cloth around the valve body and copper

tube stub to protect it from heat damage during braz-

ing. Wrap another wet cloth underneath the valve body

to protect the base paint.

NOTE − The tube end must stay bottomed in the fitting

during final assembly to ensure proper seating, seal-

ing and rigidity.

5. Install the field−provided thermostatic expansion valve

(approved for use with HFC−410A refrigerant) in the

liquid line at the indoor coil.