INSTALLATION PROCEDURE

CONTINUED

6

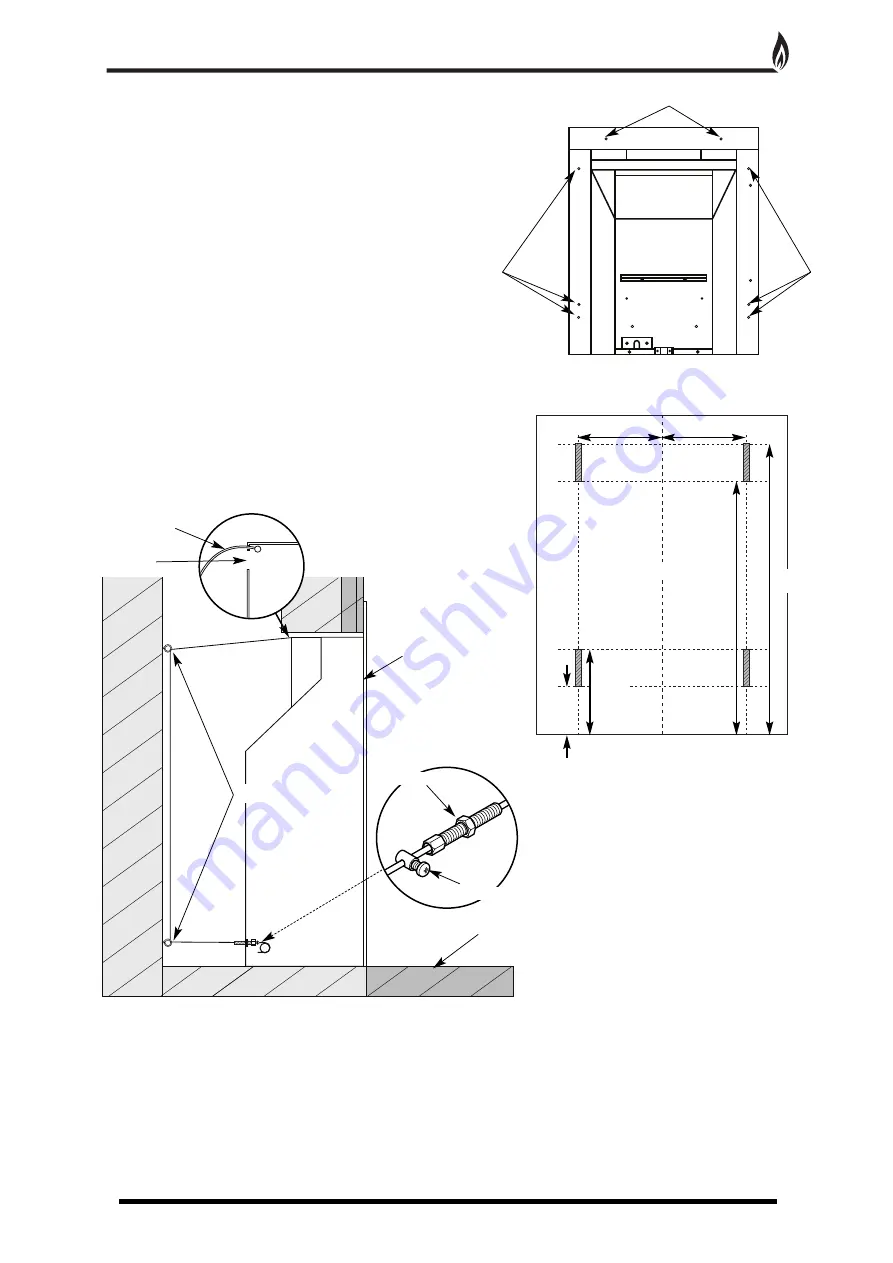

Radiant box

Hearth

Eye Bolts

Centre Line

Drill Holes for 4 eye bolts

on 112mm centre lines

between max and min height.

65mm

min

Fix the radiant box into the opening, securing into position using the cable fixing kit (Fig. 6). Do not cut off the

loose ends as the full length is required should the radiant box need refitting at any time. Coil up and securely

store underneath the burner tray.

1. Position the burner tray into the box in order to determine the length of 8mm gas supply needed and cut to

length.

2. Before making the final connection, thoroughly purge the supply pipe to clear any foreign matter, i.e. masonry

dust etc, as this could lead to blockages in the control valve and/or pilot assemblies.

3. Fix the burner in place using the four screws and make the gas connection. Carry out a gas soundness test.

ALTERNATIVE FIXING METHOD

Where the drilling of the back panel is not practical, an alternative

fixing method may be employed using the

optional

cable fixing kit

provided. Drill four holes in the rear of the fireplace opening (Fig. 5).

Securely fix the four eye bolts provided using suitable rawl plugs.

Feed one cable through each of the top holes in the rear of the

fire box.

115mm

max

500mm

min

550mm

max

112mm

112mm

Tension Nut

Cable Clamping Screw

Fig. 5

Fig. 6

Cable

Rectangular

Cutout

Insert cable into rectangular cutout

and feed the end back through the

small hole above the cutout.

Fixing

Holes

Fixing

Holes

Fixing Holes

9. When the burner tray has been removed, decide which

side of the appliance the gas supply will be entering the

radiant box and remove the relevant blanking plate. The

gas supply should be concealed as much as possible. Both

blanking plates

MUST

be re-fitted or this could seriously

impair performance.

10. With the radiant box placed in the opening, mark out

four of the eight fixing holes. Remove the box and carefully

drill and fit rawl plugs.

11. Pass the 8mm gas connection through the back of the

box and secure the box into place using four screws

(straight shank screws are recommended for marble).

Check that the outer flange of the appliance is completely

sealed against the back panel.

Fig. 4