1. General Presentation

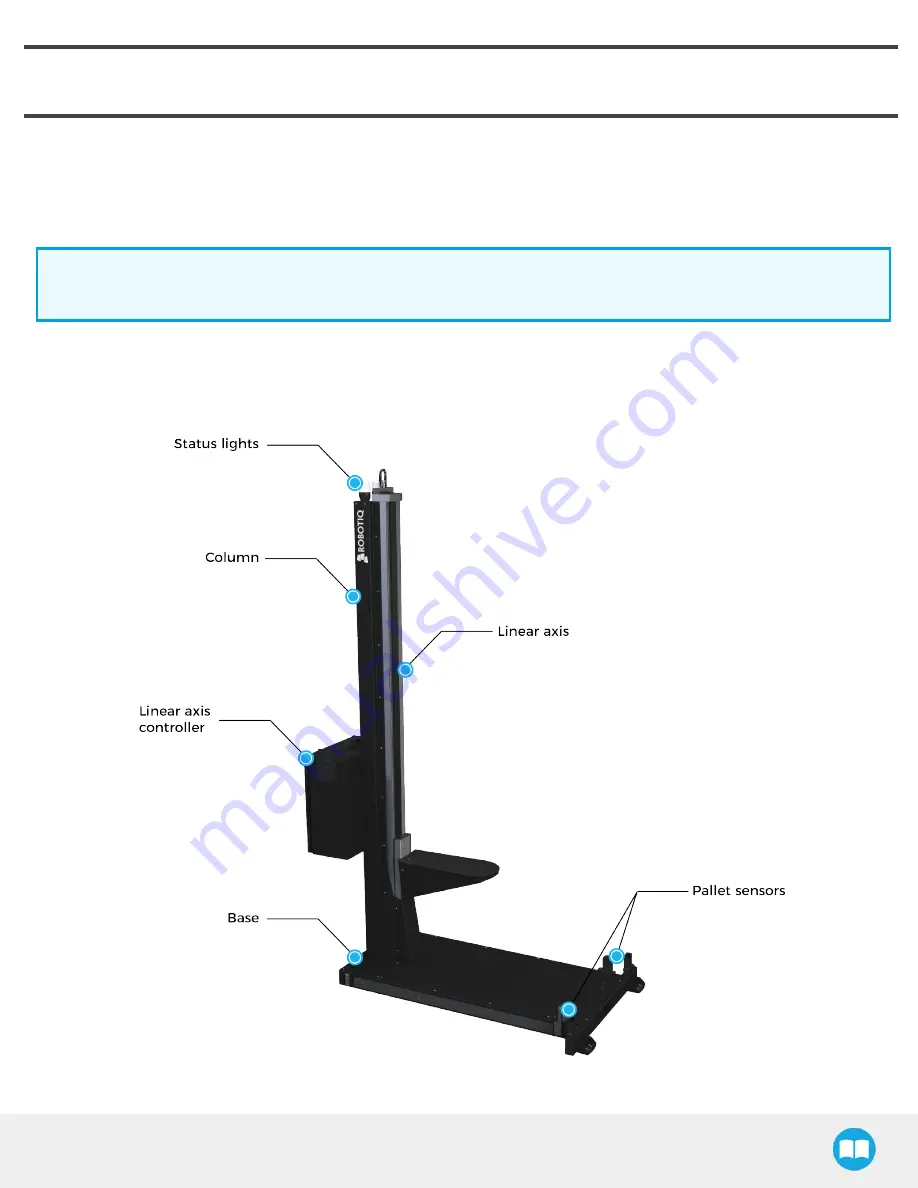

The terms " Palletizer" , " Palletizing Solution" , " Robotiq Palletizing Solution" , " Solution" and " AX Series" used in this manual all

refer to the AX Series Robotiq Palletizing Solution. The AX Robotiq Palletizing Solution is a hardware and software solution already

connected and ready to install. It is composed of a base fully integrated with a linear axis, pallet sensors, and status lights. An extra

reach gripper bracket is also included in the Solution to extend the reach of an end-of-arm tool of 200 mm from the robot's tool

flange. The Material Handling Copilot software and accessories (e.g., box sensor, anchor kit, cable management system, etc.) are

also part of the Solution.

Info

The following manual uses the metric system. Unless specified, all dimensions are in millimeters.

1.1. Palletizing Solution Components

Palletizing Solution - Instruction Manual

8

Summary of Contents for ROBOTIQ AX Series

Page 4: ...Palletizing Solution Instruction Manual 4...

Page 14: ...Palletizing Solution Instruction Manual 14...

Page 21: ...Palletizing Solution Instruction Manual 21...

Page 82: ...6 1 2 AirPick Vacuum Gripper Fig 6 1 AirPick general dimensions 82...

Page 83: ...Palletizing Solution Instruction Manual 6 1 3 Extra Reach Bracket 83...

Page 84: ...6 1 4 Bracket for Two 2 Suction Cups Fig 6 2 Two air nodes bracket s dimensions 84...

Page 110: ...1 2 2 Safety Connections Fig 12 2 Universal Robots Controller Safety Connections Schema 110...