LAUNCH

Installation Instruction for Economical Symmetric Floor-plate 2-post Lift

7

falling of the column.

The wire protective pipe on the floor plate must

be in same direction with the pipe on the column

near the base. And the floor plate would be placed

in front position.

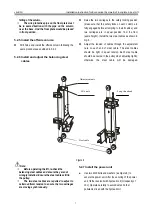

5.2.5 Install the offside column

z

Drill holes and install the offside column following the

same procedures as outlined in 5.2.3

5.2.6 Install and adjust the balancing steel

cables

z

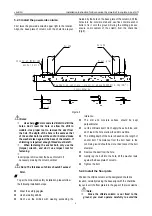

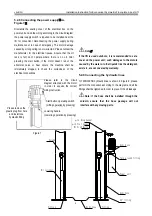

Raise the two carriages to the safety locking position

(make sure that the safety locks on each column are

fully engaged before attempting to install cables), and

two carriages are in equal position from the floor

(same height). Install the two steel cables as shown in

Fig. 6.

z

Adjust the tension of cables through the adjustment

nuts on each end of steel cable. The steel cables

should be tight in equal tension. Each steel cable

should be ensured in the pulley when adjusting tightly,

otherwise the steel cable will be damaged.

Figure 6

Note:

Before operating the lift, re-check the

balancing steel cables and ensure they are not

wrongly installed. Ensure the steel cables still in

the pulley.

The two steel cables are required to adjust to

certain uniform tension to ensure the two carriages

are moving synchronously.

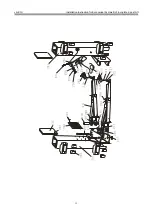

5.2.7 Install the power unit

z

Use two M10 bolts and washers (as Figure 8) to

secure the power unit. After the securing of the power

unit, fill the reservoir with hydraulic oil (oil capacity of

10L). Operate carefully to avoid dust and other

pollutants mixed with the hydraulic oil.

M16 nuts

Adjustment nuts

Long thread end

Steel cable