LAUNCH

Installation Instruction for Economical Symmetric Floor-plate 2-post Lift

16

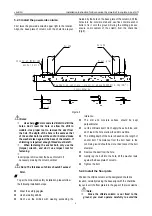

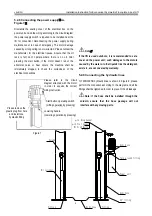

Diagram of electrical system for Single-phase motor

AC500V,20A

switch prepared

by user

KM-AC Contactor

;

M-Motor

;

SB-Start button

Diagram of electrical system for three-phase motor

KM-AC Contactor

;

M-Motor

;

SB-Start button

;

FR-Overheat Relay

The electrical working principle is as follows:

Press the start button (SB), and the contactor (KM) will be

closed; motor (M) is energized to drive the gear pump for oil

supply so as to push the carriage upward; release the start

button, and the contactor (KM) is open, then the motor (M)

will lose the power, so the carriage will stop lifting.

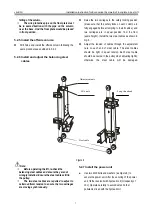

Diagram of hydraulic system

2

3

1

4

5

7

6

8

8

9

9

1 0

1 1

1-Gear pump, 2-motor, 3-oil filter, 4-check valve,

5-safety valve,6-manual lowering valve 7-Sevo flow –

control valve, 8-hose,,9-hydraulic cylinder, 10-level gauge,

11-air filter

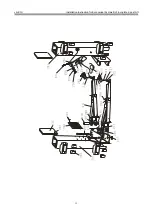

Working principles of hydraulic system:

When the button is pressed to start the motor on the power

unit, the motor 2 will be actuated to put the oil pump 1 into

motion; and oil will be sucked from the oil tank and sent to

cylinder 10 forcing the piston move upward. At this time, the

safety vale 5 is at the “Closed” position. (The pressure is

well adjusted before leaving the factory to ensure the rated

capacity. However, when the system pressure exceeds the

limit, the oil will automatically overflow). When the start

button is released, the oil supply will stop so as to stop the

lifting operation. For lowering the carriage, first start up the

motor to raise the carriage a little, pull the steel ropes on the

two carriages to disengage the safety locking status; and

then press the manual lowering handle valve 6 to lower the

carriage.