LAUNCH

Installation Instruction for Economical Symmetric Floor-plate 2-post Lift

6

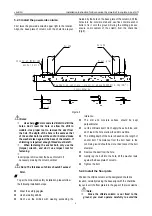

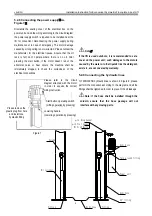

5.2.3 Install the powerside column

First raise the powerside column upper right to the location.

Align the base plate of column with the chalk line layout.

Guided by the hole on the base plate of the column, drill the

holes into the concrete slab and use five concrete anchor

bolts to fix it onto the ground. During the drilling process,

ensure no movement of the column from the chalk line

(Fig.5).

.

4000(1800wide

)

10sets of M18

×

160

25

0

anchor bolts

φ

19

Floor plate

Column

15

0

Column

Foundation concrete intensity above3000PSI(2.1Kg/mm )

2

Figure 5

Notes:

Use sharp

Φ

19mm concrete drill-bit to drill the

holes. Don’t ream the hole or allow the drill to

wobble. Use proper tool to remove the dust from

the hole. The depth of the hole is the same as that

of the anchor bolt. Insert the anchor bolt and make

the washers lean against the base of the column. If

shimming is required, enough thread must be left.

When fastening the anchor bolt, only use the

(torque) wrench, and don’t use impact tool for

fastening.

Insert proper shims under the base of column if

necessary, making the column vertical.

Note: The thickness of shims shouldn’t exceed

5mm.

。

To get the correct and safety installation, please follow

the following installation steps.

z

Wear the safety goggles.

z

Use hard alloy drill-bit.

z

Don’t use the drill-bit with wearing exceeding the

tolerance.

z

The drill and concrete surface should be kept

perpendicular.

z

Let the drill work itself. Don’t apply the extra force, and

don’t ream the hole or allow the drill to wobble.

z

The drilling depth of the hole is based on the length of

anchor bolt. The distance from the bolt head to the

concrete ground should be more than twice of the bolt

diameter.

z

Remove the dust from the hole.

z

Gently tap the bolt into the hole, till the washer rests

against the base plate of column.

z

Tighten the bolt.

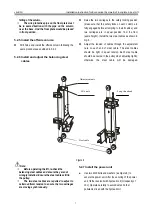

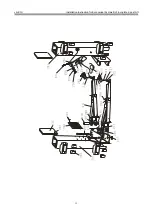

5.2.4 Install the floor plate

Position the offside column at the designated chalk line

location, carefully making the base align with the chalk line

layout. Insert the floor plate into the gaps of the two columns.

Note:

Since the offside column is not fixed to the

ground, you must operate carefully to avoid the